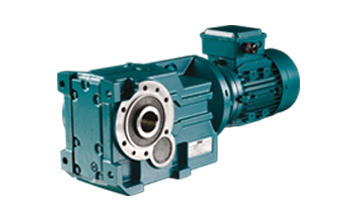

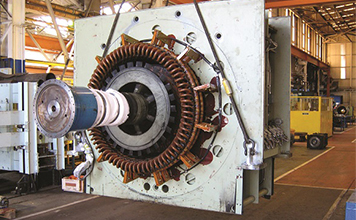

Whether you require an inline helical, worm, helical worm, or helical bevel, rest assured, we have a solution tailored for you. With thousands of variants to accommodate every shape and size imaginable, the Fenner M, C, F, K & W series gearboxes offer unparalleled versatility.

Available in modular form, our range simplifies the process of assembling a customised gearbox or geared motor that meets your exact specifications with ease and precision.

Fenner gearboxes: the smarter choice

- Quick turnaround: Built to order from stock in 3-5 days, same-day options available for emergencies

- Versatility: All popular sizes available, with output speeds ranging from 1 to 1000rpm

- Ease of maintenance: Our unique Dry-Fit motor adapter permits the removal of the motor without losing or contaminating the oil

- Customisation: Modular accessories for quick interchangeability, including output shafts, flanges, torque arms, backstops, and more.

Expert support is just a click or call away

Whatever your requirements, expert, knowledgeable support is only a call or click away. Whether it's our local Service Centre Team or our Power Transmission Technical Team based in Pensnett, we're always happy to offer selection support.