ERIKS helps Irish manufacturers' supply chain concerns

ERIKS will be exhibiting on Stand R03 at the National Manufacturing and Supply Chain Conference and ...

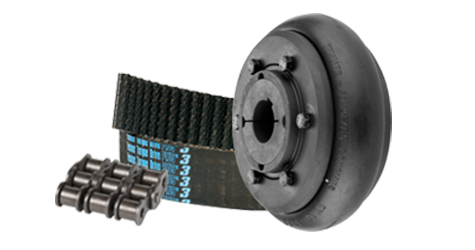

From micro to mammoth and traditional to cutting edge technology, ERIKS can design, supply and customise all open drives.

If you need an adapted chain or belt for conveying, our drives facility can build this for you in no time at all.

We offer a wide range of belts drives, chain drives and coupling product solutions to meet your requirements, please feel free to raise an enquiry on the ERIKS Ireland team using the links below and we will get back to you as soon as possible.

The Fenner friction belt range is now better than ever!

For the full range and complete technical details, visit the Fenner website.

We’re thrilled to announce that Fenner products like Quattro PLUS and Ultra belts are now available in increased stock levels at our ERIKS Fulfilment Centre of Expertise (FCE) in Oldbury.

Committed to meeting industry needs, we continuously update our stock profiles, ensuring you have the latest solutions when you need them.

Would you like more information, or request a quote?

Maybe you want to know more about innovative new Fenner products designed to meet the rigours of modern industry?

Fill in the form and we'll get back to you in no time at all. If you need a quote, tell us more about your specifications.

The new home for ERIKS News, Blogs and Case Studies - keep up to date with all the latest news and updates in one place

The latest:

ERIKS will be exhibiting on Stand R03 at the National Manufacturing and Supply Chain Conference and ...

Conveyors are a critical role in many processing applications, however, the food and beverage sector also demands hygienic and sanitisation. The Rexnord KleanTop line is one example of a belting series designed specifically for the job in question.

Making a Klean Sweep

While plastic belts are easy to clean, they are also easy to scratch and crack leaving spaces for germs to grow. Screw heads are another area for concern, where water can build-up and providing a breeding ground for bacteria.

With belting solutions such as the KleanTop 390, 2010 and 1200 Series, Rexnord overcomes the issues by using food-safe materials and ultra-hygienic designs. While Rexnord's 590 Series has an open hinge design making it easier to access for cleaning and draining water more effectively.

Keep your Cool

If your application requires cooling, Rexnord's 1090 Series has a scalloped bottom to the belt allowing it to run on a roller rather than a sprocket, ensuring it moves consistently without deadspots, it also features the open hinge design. In addition, both the 1090 and 1010 Series feature a reinforced belt edge, allowing more effective cleaning, in less time and with fewer chemicals.

Saving you time and money, each and every day

For all general enquiries use the Enquire Online form - we'll connect you with the best member of our team for your query. Alternatively, look up your local service centre...

We are proud to boast a strong team of technical specialists in each of our product and service areas. If you have a technical question a member of our team would be happy to help.

At ERIKS we strive to deliver the best quality service and products. As part of this goal we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.