Full steam ahead - Scottish distillery with Grundfos

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

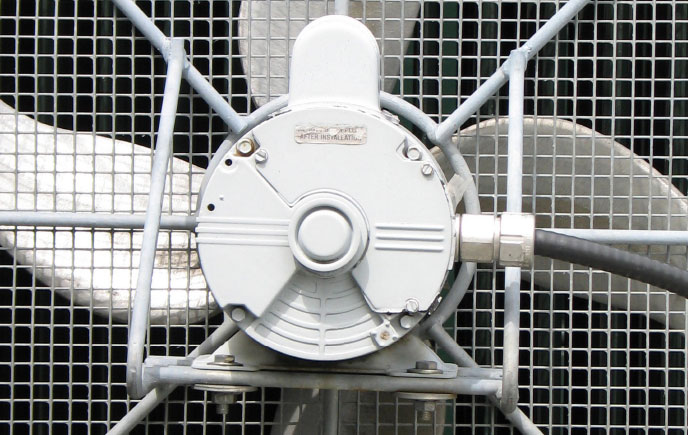

What can you find in your plant rooms? More often than not, frictional noise, energy wastage and excessive maintenance costs. Where can you find them specifically? In the fan assembly bearings of your HVAC system’s air handling unit. And how do you get rid of them? With SKF Y-bearings and Y-bearing units.

In tests, SKF’s range of low-friction Y-bearings and bearing units has been shown to have a frictional moment at least 50% lower than similar-sized standard Y-bearings. In some cases, the figure has even been as much as 75%.

Reduced friction means quieter performance, and therefore improved working conditions. Reducing frictional losses means lower energy use and greater sustainability. And last but not least, low friction is key to longer service life and less maintenance.

Ideal for air handling systems in factories, offices, shops, restaurants, hospitals and hotels, the SKF Y-bearings range is just as effective in applications from industrial fans to textile machinery and conveyors.

The main technological improvements in the new SKF range are a new and highly effective contact seal and a new low-friction grease.

The lowered friction reduces the running temperature of the bearings by up to 30°C compared to standard bearings, depending on the operating conditions. Since the industry rule of thumb states that a 15°C temperature reduction doubles the service life of lubricant grease, that’s a significant advance.

Specially formulated low noise, low friction, water resistant, lithium-based SKF LEGE 2 grease offers extra efficiency and longevity. Combined with the bearings’ new integral seals, it ensures that in normal circumstances there will be no need for relubrication during the bearings’ lifetime.

This not only saves time, effort and cost, but also addresses the environmental concerns raised by relubrication.

SKF low-friction Y-bearings are available in a wide range of sizes and configurations.

They can also be supplied in fully-assembled SKF low-friction Y-bearing units with composite housings, optimised as necessary for specific applications. Lightweight, cost-effective and easy to mount, they’re especially suitable for users requiring reliability and minimal maintenance, at high speeds with moderate loads.

The housings are made from polyamide material reinforced with glass fibre, and are resistant to a variety of chemicals and dilute acids. For maximum mechanical strength, durability and thermal stability, a steel coil is moulded within the housing body, while the mounting bolt holes are lined with zinc-coated steel. As a result, the unit’s radial breaking load is higher than the basic static load rating of the Y-bearing it contains.

Along with excellent corrosion and UV resistance, the material offers good tolerance of high and low temperatures, is paintable, and can be recycled after use. Although up to 75% lighter, the housing is dimensionally interchangeable with cast iron units conforming to ISO 3228 – so upgrades are easy.

SKF low-friction Y-bearing units are designed for easy, uncomplicated mounting.

An initial misalignment of up to 5° is accommodated by the bearing’s spherical outer surface and the housing’s matching bore. The bearing’s inner ring can be extended on one or both sides, in line with the desired locking method.

For compliance with health and safety regulations, the units can be supplied with optional SKF ECY end covers which simply snap into the recesses in the housing bore. Made from polypropylene, they’re strongly resistant to most chemicals, and tolerant of temperatures as high as 100°C. As an alternative, SKF ECW end covers have the added option of a drain hole which can be easily opened when necessary.

So why choose SKF Y-bearings and Y-bearing units? Because, as SKF Channel and Platform Development Manager, Bearings and Units, David Oliver says: “Whatever your situation, we can configure the right SKF low-friction Y-bearing unit to reduce total cost of ownership.”

“With faster, easier mounting, reductions in energy and grease consumption, lower maintenance costs and longer service life, these units save time and money all the way. And they make buildings quieter and more comfortable, while minimising impact on the wider environment.”

Get the latest updates from ERIKS including:

Choose any or all of these via the ERIKS Subscription Centre!

Our Know+How brings together the best of the latest Know+How Hub articles in one easy to digest magazine, covering the following topics:

That's why its the leading magazine for maintenance engineers from ERIKS.

Want Know+How Magazine delivered direct to your door? Visit the ERIKS Subscription Centre to opt-in!

Take a look at our latest updates...

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

Looking for a custom Product quote? Need an answer to a Technical question? Looking for Careers/HR support? Want to work with us? Interested in our Digital Trading solutions? Have a finance question? Send us your enquiry and a member of the ERIKS team will be with you quickly.

We strive to deliver exceptional quality service and products. As part of this goal, we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

At ERIKS we strive to deliver the best quality service and products. As part of this goal we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

Call us: +441215086000