Full steam ahead - Scottish distillery with Grundfos

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

In a modern world with so much CCTV in operation, it’s hard not to feel like we’re constantly under the microscope. And for companies in the food and beverage sector, with the growing concerns of contamination and trust from the public somewhat diminishing, eyes are open wider than ever before.

An upsurge in food contamination cases has called for a higher demand for machine safety and reliability, while easier methods of maintenance are also high on the list of priorities. Cost-effective production must be facilitated, and outstanding performance and maintenance operation assured.

So, with such a need for continuous high-speed operation, and meeting the most stringent hygiene standards for years, what is it that’s really needed?

The answer: reliable and robust bearings.

Bearing applications in the food and beverage sector are vast and varied, from raw material cutting and mixing (primary) to conveying, inspection and packing solutions (secondary). But they all have one thing in common. They must be safe and sanitary.

Essentially, the food production process is divided into two main steps: pre-processing – washing, cutting and sorting; and post-processing – distribution, filling and packing. And NSK’s core technologies have responded to the demanding needs of the industry, contributing to improved performance in food processing machinery.

Since the discovery to turn sugarcane into granulated crystals, sugar has become a daily commodity. We have it in our tea. We love it on our cereal. We even borrow it to and from our neighbours. But there’s so much to the process until it tingles our tastebuds - and NSK’s innovative technology has hit the sweet spot for many sugarcane mills across the globe.

From harvesting and preparation to transportation, each step of the process is handled with machinery that is purpose-built to operate in extremely harsh conditions.

And with operating environments subject to drastic changes, the correct bearings, such as the Silver-Lube® and Life-Lube® series, must be installed at the earliest stage to ensure peak performance, efficiency and quality are guaranteed.

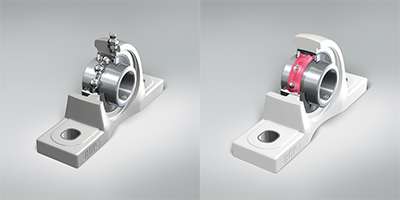

Comprising high-grade Stainless Steel bearing rings, cage and balls with seal core and grubscrews, grease nipples and bolt-hole liners, the Silver-Lube® series’ thermoplastic polyester resin housing is not only non-corrodible, but has excellent resistance to cleaning agents and chemicals. And at a wide temperature range - from -20°C to +90°C.

In comparison, the Life-Lube® series combines the chemical properties of the Silver-Lube® with the excellent sealing and lubricating attributes of moulded oil inserts. Further to the design, they’re manufactured with paint-free housings to prevent chipping and flaking, meaning they’re ideal for environments where contact with water and process fluids is unavoidable.

A European producer of machines for vegetable treatment was experiencing costly problems with its barrel washers. As the washer drum rotated, it placed the bearings under water once per spin. This continuous cycle left the bearings needing to be replaced every three months due to water washout, leading to severe corrosion.

The issue was investigated and a bearing arrangement with better sealing performance was proposed, and special Triple-Lip Sealed bearings were installed.

The new bearing arrangement contained nitrile rubber triple-lip units, which were bonded to the protective pressed steel shield to help withstand exposure to water and other contamination, and mounted on the shaft with a balled setscrew to provide a greater resistance to loosening.

The simple replacement and installation provided the customer with a cost saving of €56,600 through increased productivity, while extended re-lubrication intervals greatly reduced maintenance costs and increased the bearings lifecycles from three months to more than seven.

As the industry continues to develop, eyes will get wider and wider, with standards becoming higher and higher. Only by investing in the right technology for your application, ideally at the opening phase, will you ensure that your production and efficiency KPIs are met and regulations adhered to.

Then, you will reap the benefits of higher productivity, reduced downtime, minimised maintenance, and a lower Total Cost of Ownership.

Get the latest updates from ERIKS including:

Choose any or all of these via the ERIKS Subscription Centre!

Our Know+How brings together the best of the latest Know+How Hub articles in one easy to digest magazine, covering the following topics:

That's why its the leading magazine for maintenance engineers from ERIKS.

Want Know+How Magazine delivered direct to your door? Visit the ERIKS Subscription Centre to opt-in!

Take a look at our latest updates...

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

Looking for a custom Product quote? Need an answer to a Technical question? Looking for Careers/HR support? Want to work with us? Interested in our Digital Trading solutions? Have a finance question? Send us your enquiry and a member of the ERIKS team will be with you quickly.

We strive to deliver exceptional quality service and products. As part of this goal, we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

At ERIKS we strive to deliver the best quality service and products. As part of this goal we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

Call us: +441215086000