Full steam ahead - Scottish distillery with Grundfos

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

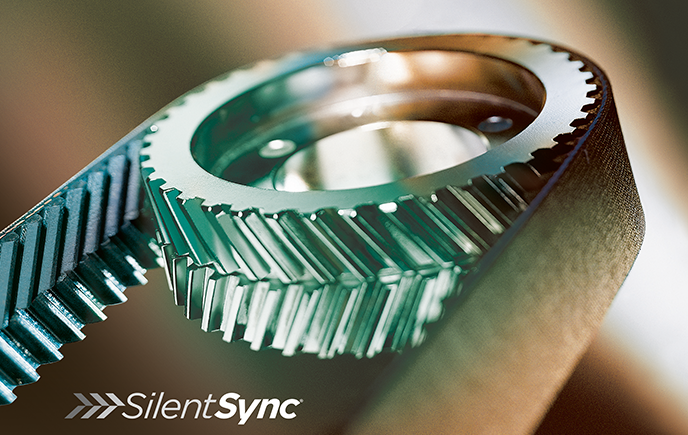

Industrial noise is a Health and Safety issue. We said: INDUSTRIAL NOISE IS A HEALTH & SAFETY ISSUE! And a big contributor to noise are timing belts. But, very quietly, the Conti® SilentSync from ContiTech is changing all that – as well as reducing vibration, increasing efficiency, and cutting system costs.

When noise is a problem in an industrial environment there are two ways to resolve it: mask it or eliminate it. Masking noise is very costly to achieve effectively – but you may think eliminating noise is more difficult. In fact, it’s not.

And if you eliminate it by changing to the Conti SIlentSync belt, you’ll achieve other benefits too.

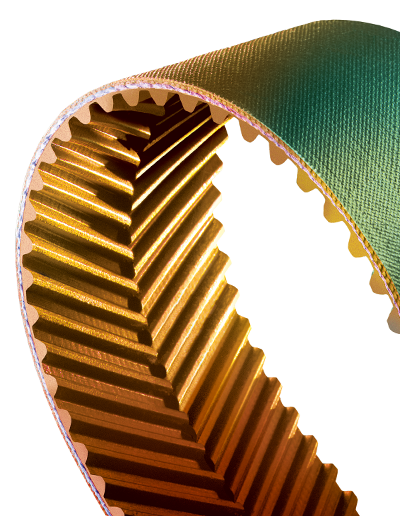

One of the leading sources of noise from ordinary timing belts is when the teeth on the belt engage with the sprockets on the pulley. The Conti SilentSync belt counters this, by using a helical offset tooth profile.

While conventional synchronous belts engage with the pulley in steps, which leads to vibration and noise, Conti SilentSync effectively “rolls” into the pulley in a continuous engagement, which is not only much quieter but also more efficient. The offsetting of the teeth also increases the smoothness of the engagement, which again helps to reduce noise.

The difference in noise levels between Conti SilentSync and a conventional belt is up to 19dB. Given the logarithmic nature of the decibel scale (e.g. a 3dB reduction is actually 50% quieter), you can see – or rather hear – the difference a SilentSync belt can make. In an environment such as robotics, where high-speed drives and people are in close proximity, this is a major contribution to health and safety, and to creating a more pleasant, less tiring, and therefore more efficient workplace.

Another source of timing belt noise – and of reduced efficiency – is vibration. Again, the Conti SilentSync belt overcomes this – and not just by a small margin. In fact the SIlentSync delivers up to 20% lower vibrations, and 98% efficiency. That’s 5% more efficient than conventional V-belt drives.

Reduced vibration is also an advantage in drive applications where high-precision is a requirement. SilentSync enables very accurate operation, and its self-tracking capability ensures the belt engages with the pulley without moving from side to side. The profile also prevents back-and-forth movement – or backlash – which again increases accuracy.

In addition, the precise belt alignment, increased ratcheting resistance, increased horsepower rating and improved stress distribution all help to withstand the shearing action of the high-output drives, and to reduec wear.

While conventional belts have a fibreglass tension member, the Conti SilentSync features an exceptionally strong aramid cord. This will show no signs of aging and little appreciable elongation, so generally no retensioning is required yet absolutely synchronous power transmission is assured.

The belt backing is made of the same material but with a polyester fabric incorporated, making it highly flexible. It’s even suited to reverse flexing if needed. The belt teeth are moulded from synthetic rubber, then made wear-resistant with a specially-treated polyamide fabric. The material is resistant to oil, coolants, ozone and heat, with an operating temperature range – depending on the application – from -40°C to +95°C.

It's also very strong, at up to 80% stronger than conventional synchronous belts, and up to 50% stronger than the raw-edge premium V belts of the same width. This offers the opportunity to reduce the width of the V-belt systems without reducing their output - saving on system real estate, and cutting costs.

For easier belt selection, Conti SilentSync uses a unique colour-coding system.

With two pitches (8mm and 14mm) and seven widths (16mm, 32mm, 35mm, 52.5mm, 64mm, 70mm and 105mm) the range is colour-coded (yellow, white, purple, blue, green, orange and red respectively), for easy recognition and identification, and to ensure belts can be quickly matched for replacement.

When a product has so many advantages, you may be surprised that you haven't heard of it before. In fact it's such an improvement on traditional belts, you'd expect the manufacturer to make a big moise about it. But for a belt as quiet as Conti SilentSync, that probably didn't seem appropriate. Ssssh!

Reliability is a buzzword that is seemingly always on the tip of industry tongues, but it’s clear that businesses need to be more proactive in their attempt to maximise their assets.

In this issue, we look beyond equipment, but at processes, systems, strategy and communication.

Get the latest updates from ERIKS including:

Choose any or all of these via the ERIKS Subscription Centre!

Our Know+How brings together the best of the latest Know+How Hub articles in one easy to digest magazine, covering the following topics:

That's why its the leading magazine for maintenance engineers from ERIKS.

Want Know+How Magazine delivered direct to your door? Visit the ERIKS Subscription Centre to opt-in!

Take a look at our latest updates...

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

Looking for a custom Product quote? Need an answer to a Technical question? Looking for Careers/HR support? Want to work with us? Interested in our Digital Trading solutions? Have a finance question? Send us your enquiry and a member of the ERIKS team will be with you quickly.

We strive to deliver exceptional quality service and products. As part of this goal, we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

At ERIKS we strive to deliver the best quality service and products. As part of this goal we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

Call us: +441215086000