Full steam ahead - Scottish distillery with Grundfos

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

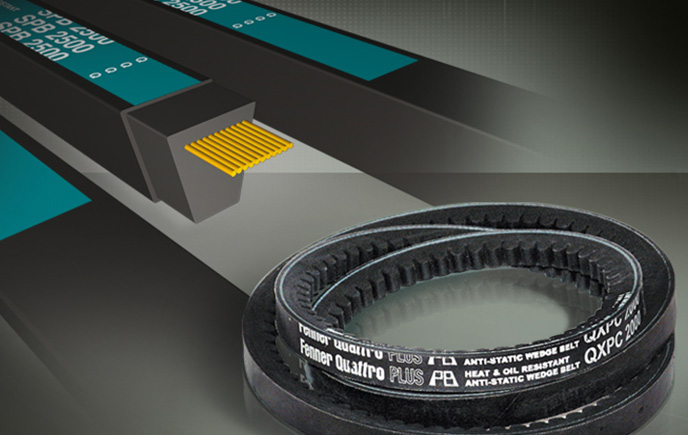

Making sure you get the best out of your belt drives is all down to SCIENCE. That’s not us shouting, and it’s not physics or chemistry. It’s: Select Correctly Install Effectively Never Compromise Efficiency.

So it may be SCIENCE but its certainly not rocket science. Its just a set of three simple rules which will help you ensure your drive selection performs at its optimum. Let's look at them one by one.

Selecting the right belt for the right drive will help you to achieve the performance you need, with the smallest number of belts. Some belts, for example, offer very high power capacity, whereas others offer high length stability. Some are medium efficiency but low power capacity, and some are very highly rated in all three areas: power capacity, efficiency and length stability.

It’s up to you to decide which properties are most important and appropriate for the application you have in mind. But you don’t have to do it all alone. The Fenner On-Line belt Selector will take you through the whole selection process and recommend the right belt for your needs.

Once you’ve selected the right belt, the next step is to install it correctly – otherwise it will make little difference which belt you’ve selected: it simply won’t perform as it should. On the other hand, effective, correct installation will ensure your belt drive lasts longer and works more efficiently throughout its service life.

One of the most common mistakes – made in 70% of installations – is to fit a new belt to a worn pulley. This wastes energy and not only compromises the efficiency but also the lifespan of the new belt.

In fact, the kind of lifespan you can expect from a new belt decreases drastically depending on the pulley it’s fitted to:

Often, the pulley won’t be replaced because it’s considered too costly to do so. But if a pulley with worn grooves is replaced at the same time as the new belt is installed, it will quickly pay for itself by restoring optimum drive efficiency, by lengthening the life of the belt, by reducing maintenance requirements and by minimising downtime.

You can easily check whether or not a pulley needs replacing, using a gauge such as the Fenner Pulley Groove Gauge. They’re available from your local ERIKS Service Centre, and every maintenance engineer should have one in his toolbox.

Belt drives are too often overlooked, when they should be an integral part of a planned maintenance schedule. If they are, you can expect to:

You can download a copy of the latest Fenner brochure here or contact your usual ERIKS Service Centre for more information.

Make sure you’ve got the right belt for the job with the Fenner On-Line Belt Selector, and make sure you add belts to your next round of planned maintenance. It may not strictly be science, but if you want to get the most from your belts and your machinery, it’s logical.

Get the latest updates from ERIKS including:

Choose any or all of these via the ERIKS Subscription Centre!

Our Know+How brings together the best of the latest Know+How Hub articles in one easy to digest magazine, covering the following topics:

That's why its the leading magazine for maintenance engineers from ERIKS.

Want Know+How Magazine delivered direct to your door? Visit the ERIKS Subscription Centre to opt-in!

Take a look at our latest updates...

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

Looking for a custom Product quote? Need an answer to a Technical question? Looking for Careers/HR support? Want to work with us? Interested in our Digital Trading solutions? Have a finance question? Send us your enquiry and a member of the ERIKS team will be with you quickly.

We strive to deliver exceptional quality service and products. As part of this goal, we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

At ERIKS we strive to deliver the best quality service and products. As part of this goal we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

Call us: +441215086000