Full steam ahead - Scottish distillery with Grundfos

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

Food producers need no guidance from engineers on maintaining cleanliness and hygiene in their production processes. Correct hygienic procedures, wash-down regimes and so on are second nature to reputable producers. But if the equipment being used is unhygienic in its design, then what chance do they have?

It’s a small irony that procedures to achieve a clean environment may create the very problems they’re intended to eliminate. Frequent wash-downs of equipment and machinery largely remove food residues, and using chemicals helps to kill bacteria. However, the water also facilitates the kind of wet ambient environment where bacteria thrive if they can only get a toehold.

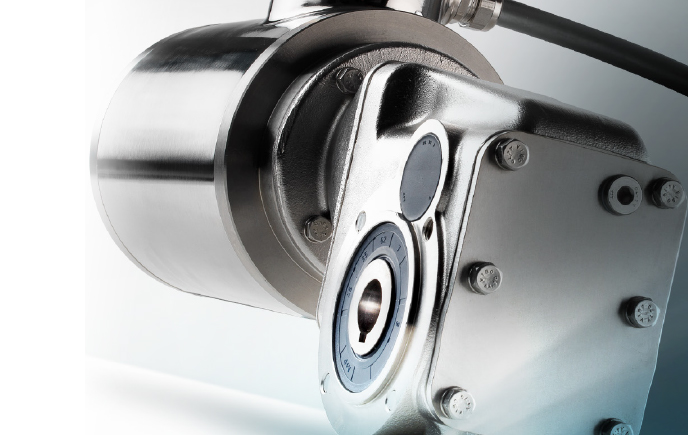

Unfortunately, that toehold is often found in gears and motors. In fact, 90% of bacterial contamination in the sector is caused by poor hygienic design, and gears and motors deserve the largest share of the blame.

As a leading gears and motors manufacturer, the Fenner brand has extensive experience of the ways in which poor design can offer a welcome mat to bacteria.

Bacteria thrive in warm and moist conditions. Most motors lack condensation control, so when they are warmer than the air around them, condensation can quickly build up – making bacteria feel perfectly at home.

In addition, where there’s moisture there’s corrosion, which can shorten a motor’s operating life, increase downtime and maintenance costs, and lead to a higher total cost of ownership.

Corrosion can be a particular problem in gear housings and bearings, as a result of condensation, or water ingress during wash-downs.

In a worst-case scenario, corrosion can break off and make its way into the food production process and on into the product itself. Compared with that, the fact it can also shorten the equipment’s working life looks like a minor inconvenience.

Even a thorough wash-down regime won’t necessarily remove food debris from hard-to-reach areas such as cooling ribs, hollows and sharp edges. Accumulated debris is a bacterial breeding ground, and in time the bacteria could enter the food product – with all the risks to customers and brand reputation that implies.

As if all that wasn’t enough to worry about, there are external pressures too.

Producers are being ever more tightly squeezed on price and margin by retailers. Then there are regulations to adhere to and certifications to acquire, such as those from the British Retail Consortium and International Food Standards. They mean extra work, additional admin., and yet more cost.

Meanwhile retailers are under pressure too: to ensure that the food offered to their customers is of the highest standard. All it takes is one slip-up to attract enormous media attention and serious reputational damage.

Many food producers are turning to Hazard Analysis and Critical Control Points (HAACP) as a way of reducing the risks. This helps with risk identification, and reduction or elimination through changes to equipment and procedures.

This is also where engineers and engineering can help

For example, ERIKS has established a three-step action plan for food producers, to ensure that the gears and motors they buy are not only hygienic and compliant, but also avoid all three deadly sins of engineering design.

More hygienic systems inevitably reduce cleaning costs.

In fact, ERIKS estimates that food processors could save up to 60% thanks to shorter cleaning cycles and reduced disassembly and reassembly. Stainless steel geared motors are quicker to clean because, for example, they have no need for covers, which take extra time to clean. Stainless steel also needs smaller quantities of water and chemicals for an equally effective clean – making it a more sustainable choice.

Minimising condensation leads to less corrosion, less monitoring and longer Mean Time Between Failure. One food producer customer of ERIKS replaced a motor with the new Fenner Hygienic Geared Motor, and achieved an eight-fold improvement in operating life. Maintenance teams are also freed to concentrate on projects which benefit the entire production process, rather than firefighting gear and motor failure.

When you start with equipment which is designed and engineered to be hygienic – like Fenner Hygienic Motors and Hygienic Geared Drives – cleanliness is easier to achieve, costs can be reduced, and the risk of non-compliance is eliminated. A clean sweep, in fact.

Get the latest updates from ERIKS including:

Choose any or all of these via the ERIKS Subscription Centre!

Our Know+How brings together the best of the latest Know+How Hub articles in one easy to digest magazine, covering the following topics:

That's why its the leading magazine for maintenance engineers from ERIKS.

Want Know+How Magazine delivered direct to your door? Visit the ERIKS Subscription Centre to opt-in!

Take a look at our latest updates...

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

Looking for a custom Product quote? Need an answer to a Technical question? Looking for Careers/HR support? Want to work with us? Interested in our Digital Trading solutions? Have a finance question? Send us your enquiry and a member of the ERIKS team will be with you quickly.

We strive to deliver exceptional quality service and products. As part of this goal, we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

At ERIKS we strive to deliver the best quality service and products. As part of this goal we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

Call us: +441215086000