Full steam ahead - Scottish distillery with Grundfos

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

The slow food movement is probably the best known. But there’s also slow travel. Slow fashion. And in the waste water industry, with a s-l-o-w speed of just 1-3rpm, there’s the waste tank half-bridge wall drive. But as one utility company’s current drive units were becoming slowly obsolete, a fast response was needed from ERIKS.

Slowly crawling around the waste tank walls, half-bridge wall drives scrape the bottom of the tank to agitate and aerate the liquid – encouraging the aerobic activity which leads to breakdown of the waste.

The exceptionally slow speed means that any build-up of waste against the scraper happens at an equally slow rate, allowing the scraper to continue in operation for a long period of time in spite of it. However, if the build-up is not spotted and removed in time, ultimately it leads to a catastrophic failure.

Despite this potential for failure, one utility company’s wall drives – manufactured by a now long-defunct engineering company and incorporating Brauer wheels and double-reduction drive units – had been in operation for over thirty years.

But now they were beginning to show signs of age. These included significant wear within the castings, and a loss of tolerance in the bearings.

ERIKS had been working with the customer for some time to maintain the units and keep them operational for as long as possible, until the level of failure amongst obsolescent parts made this no longer cost-effective.

After such a length of time and so much wear, it was no longer possible to re-machine the bearing housings back to the original tolerances, which meant efficiency was being lost.

ERIKS had been working with the customer for some time to maintain the units and keep them operational for as long as possible, until the level of failure amongst obsolescent parts made this no longer cost-effective.

After such a length of time and so much wear, it was no longer possible to re-machine the bearing housings back to the original tolerances, which meant efficiency was being lost.

At the same time, the cost of new worm and wheel sets was becoming unsupportable, especially when the amount of plant downtime to install replacements was taken into account.

At the same time, the cost of new worm and wheel sets was becoming unsupportable, especially when the amount of plant downtime to install replacements was taken into account.

One of the major reliability improvements ERIKS’ engineers were looking for was in avoiding the risk of catastrophic failure.

The Fenner CYCLO is the ideal solution, thanks to its exceptionally high shock capacity. Whereas most units have a shock capacity of just 200%, the Fenner CYCLO has a shockload rating of up to 500% of torque rating.

This high rating, combined with the slow speed at which the debris and therefore the load build up, gives more time for one of two things to happen. Either the debris will clear itself naturally over time, which then restores the normal load, or the unit will have plenty of time to alert the control panel so it can be turned off and the debris manually removed – long before the load is sufficient to cause catastrophic failure.

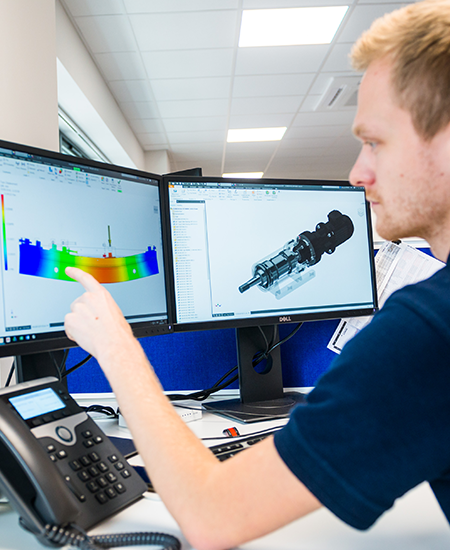

This particular utility company has over 200 half-bridge wall drives in operation, all of which are coming to the end of the useful service life. To help them prepare for the inevitable need to replace their existing units – whilst maintaining continuity of operations – ERIKS have now created a modular solution.

This comprises a standalone shaft housing assembly with parallel and taper shaft options – engineered by ERIKS – a bearing housing, a plug-in Fenner CYCLO gearbox with a wide range of output speeds and an IEC frame dry fit motor. The assembly features adjustable feet to allow for different base-to-centre heights, and the bearing housing can be used as a slave unit to accompany the drive unit.

With these modular components kept in stock, when an in-service unit fails it takes only 2-3 days to assemble a complete drive operating to the customer’s specified ratio, and to deliver it ready for installation.

Other utility companies can take advantage of ERIKS’ experience in the industry with an obsolescence survey. This enables ERIKS to see critical plant in operation, to understand the issues and commonalities across sites, and to devise a service exchange programme to maintain reliable operation.

And even if the utility companies’ process is a slow one, ERIKS’ service won’t be.

Reliability is a buzzword that is seemingly always on the tip of industry tongues, but it’s clear that businesses need to be more proactive in their attempt to maximise their assets.

In this issue, we look beyond equipment, but at processes, systems, strategy and communication.

Get the latest updates from ERIKS including:

Choose any or all of these via the ERIKS Subscription Centre!

Our Know+How brings together the best of the latest Know+How Hub articles in one easy to digest magazine, covering the following topics:

That's why its the leading magazine for maintenance engineers from ERIKS.

Want Know+How Magazine delivered direct to your door? Visit the ERIKS Subscription Centre to opt-in!

Take a look at our latest updates...

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

Looking for a custom Product quote? Need an answer to a Technical question? Looking for Careers/HR support? Want to work with us? Interested in our Digital Trading solutions? Have a finance question? Send us your enquiry and a member of the ERIKS team will be with you quickly.

We strive to deliver exceptional quality service and products. As part of this goal, we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

At ERIKS we strive to deliver the best quality service and products. As part of this goal we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

Call us: +441215086000