Full steam ahead - Scottish distillery with Grundfos

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

Your production assets all have a job to do. But that’s not all you want from them. What about maximising safety? Minimising water use? Reducing energy usage? And all while optimising productivity, of course. That's why these are four pillars of the Rexnord Engineered Sustainability product program: the program that proves sometimes engineering has all the answers

Balancing all the conflicting demands you face against all the different targets you’re given is your day-to-day challenge. So when an original equipment manufacturer comes up with a program that helps you do just that, it’s worth taking notice.

And with conveyors playing such a large part in production lines, they can play a large part in delivering on your requirements too.

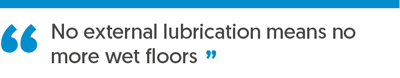

Naturally, all other considerations have to come second to safety. In the beverage filling industry, for example, slippery floors are a hazard, as a result of spillages from conveyed products. PET bottles are relatively unstable and highly susceptible to falling when conveyed on a high-speed filling line. These high-speed lines also use large quantities of water for external lubrication, and that can lead to slippery floors too.

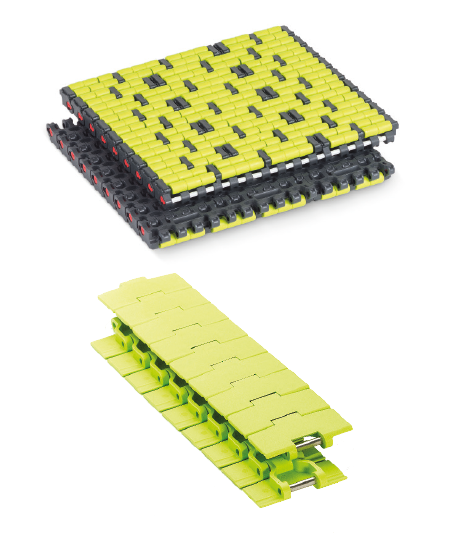

Rexnord’s Engineered Sustainability program helps to eliminate both problems. Firstly, Rexnord MatTop Chain is exceptionally flat, so helping PET bottles to stay upright. And secondly, Rexnord conveyor products which need no external lubrication mean no more, potentially slippy wet floors.

Plus, eliminating lubrication servicing means removing the need for engineers to be in close contact with fast-moving machinery, and the risks that creates.

High levels of water use for external lubrication, and cooling of high-speed corner tracks, are not only a safety hazard, and unsustainable in themselves, but also generate large quantities of waste water for collection.

The Rexnord Engineered Sustainability program can reduce – and in some cases eliminate – external lubrication and the associated problems.

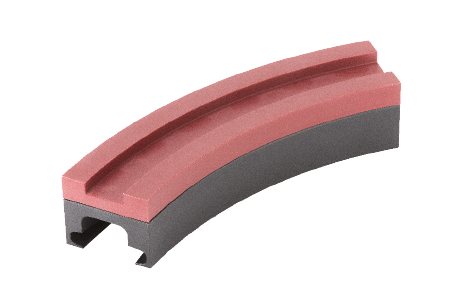

Rexnord plastic chains, for example, are self-lubricating and suitable for “dry running” even at high speeds. And for conveyor lines which need to turn corners, there are Rexnord Magnetflex® Combi-X Curves, with integrated Ultra Low-Friction (ULF™) upper parts. These not only offer consistent low friction between chain and curve, but also minimal headshaft tension, long wear life, and low noise.

The average beverage filling and packaging line typically contains around 80-100 conveyors, each with its own power hungry drive. How much power each drive demands depends on a combination of varying factors, such as weight, conveyor layout and friction between contact surfaces.

Rexnord’s Engineered Sustainability program can help you to choose the most effective combination of state-of-the-art conveyor materials, to minimise friction and therefore reduce energy use. The 1005 XLBP Series Chain, for example, is only 40% of the weight of a traditional modular LBP chain, and creates 30% less friction between packs and chain during accumulation.

The 1005 XLBP Series can realise even more energy-savings by extending conveyor lengths, which minimises the number of drives required.

Safety, water consumption and energy-use are all important. But at the end of the day – and the conveyor line – productivity is what counts.

As the critical connection between machines, conveyors provide optimal product flow and buffering capacity, to ensure consistent, reliable production at optimum speed. Which means it’s the reliability and durability of your conveyor components which determine total uptime and cost, to keep line performance at the required level.

By upgrading your conveyors through the Rexnord Engineered Sustainability program – utilising state-of-the-art materials for chains and components – you can increase productivity without compromising on your other aims.

Which just goes to prove that the quickest and most sustainable way to reach all your goals, is by conveyor.

Get the latest updates from ERIKS including:

Choose any or all of these via the ERIKS Subscription Centre!

Our Know+How brings together the best of the latest Know+How Hub articles in one easy to digest magazine, covering the following topics:

That's why its the leading magazine for maintenance engineers from ERIKS.

Want Know+How Magazine delivered direct to your door? Visit the ERIKS Subscription Centre to opt-in!

Take a look at our latest updates...

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

Looking for a custom Product quote? Need an answer to a Technical question? Looking for Careers/HR support? Want to work with us? Interested in our Digital Trading solutions? Have a finance question? Send us your enquiry and a member of the ERIKS team will be with you quickly.

We strive to deliver exceptional quality service and products. As part of this goal, we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

At ERIKS we strive to deliver the best quality service and products. As part of this goal we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

Call us: +441215086000