Full steam ahead - Scottish distillery with Grundfos

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

Can you guess which drive train component is “the most critical non-critical component”? It is… the coupling. And by applying an innovative Rexnord solution to couplings for centrifugal pumps – specifically in the oil refining and petrochemical industries – you can increase production efficiency and reduce your Total Cost of Ownership (TCO).

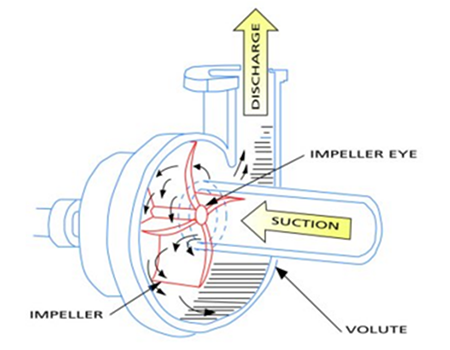

The flexible coupling connecting a centrifugal pump to its motor is small in size, small in monetary value, but huge in terms of its criticality. When operating effectively, it should not only transmit power from the motor to the pump, but also protect the connected equipment from potential damage due to equipment misalignment. It should optimise efficiency, prolong bearing life and – if built to the required standards – help ensure safety in explosive atmospheres.

The Rexnord Thomas® XTSR71 Disc Coupling does all these things, and more. Its additional features and benefits make it the best possible choice for your centrifugal pump application.

The unique strength of the Rexnord Thomas XTSR71 Coupling is that it provides very high torque density. Or in other words, it transmits a disproportionately high amount of torque for its diameter and mass.

Most all-metal disc couplings deliver torque through a combination of friction and shear, which increases the likelihood of catastrophic coupling failure. However the Rexnord Thomas XTSR71 Coupling delivers torque principally through friction. Which means less stress and less risk of catastrophic failure.

Combine this with its reduced size and mass, and it definitely punches above its weight.

The high torque-to-mass ratio of the Rexnord Thomas XTSR71 Coupling means you still get the torque your centrifugal pump requires. But you get it with less weight on the drive shaft, which means less overhanging weight and hence lower stresses on the pump bearings.

And that leads to all kinds of associated benefits, including:

Associated with its smaller mass, the coupling also has less inertia which can cause imbalance. And as a flexible coupling, it accommodates misalignment between the pump and motor.

All of which allows Rexnord to claim the coupling is “designed for infinite life” when operated within its design parameters.

The smaller size of the Rexnord Thomas XTSR71 is a clear benefit in terms of efficiency, maintenance and TCO. But what if it’s too small to fit the equipments’ shafts? Does it require an expensive, custom-made solution?

The answer is no. The Rexnord Thomas XTSR71 Coupling is available off-the-shelf with the ability to use oversized hubs.

Oversized hubs are simply the standard hubs of the next larger sizes, eliminating the need to use non-standard components or upsize the entire coupling to accommodate larger shaft sizes. With shaft size practically eliminated as a selection limitation, nearly any pump & motor combination can benefit from this most cost-effective of couplings.

Lowering your TCO through the use of standard, low maintenance, long-life components is important. In the kind of explosive atmosphere often found in the oil refining and process industries, safety is more important still.

The Rexnord Thomas XTSR71 Coupling meets:

Which proves you don’t have to reduce your safety levels when you reduce the size, mass and TCO of your centrifugal pump coupling.

In disc coupling design, manufacturers must balance maximising torque density with optimising durability.

Historically manufacturers have offered products with conservative torque ratings to ensure longer life, but this leads to higher cost and a heavier coupling. Which can in turn lead to greater bending moment on the shaft, more vibration, and increased wear on bearings and seals.

As a Technical White Paper (Disc Coupling Dilemma: Torque Density vs. Durability. 2013) Rexnord carried out a torque density analysis, including a weight comparison of manufacturers’ couplings which met or exceeded torque and bore requirements for a NEMA 449T motor frame.

The results show that the heaviest coupling for this application is more than 45% heavier than the lightest. The lightest (Rexnord Thomas XTSR71 ) is therefore the most efficient design for the tested application.

For more information, please don't hesitate to contact our Power Transmission product business unit on 0121 508 6000 to discuss your options further or enquire online today.

Get the latest updates from ERIKS including:

Choose any or all of these via the ERIKS Subscription Centre!

Our Know+How brings together the best of the latest Know+How Hub articles in one easy to digest magazine, covering the following topics:

That's why its the leading magazine for maintenance engineers from ERIKS.

Want Know+How Magazine delivered direct to your door? Visit the ERIKS Subscription Centre to opt-in!

Take a look at our latest updates...

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

Looking for a custom Product quote? Need an answer to a Technical question? Looking for Careers/HR support? Want to work with us? Interested in our Digital Trading solutions? Have a finance question? Send us your enquiry and a member of the ERIKS team will be with you quickly.

We strive to deliver exceptional quality service and products. As part of this goal, we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

At ERIKS we strive to deliver the best quality service and products. As part of this goal we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

Call us: +441215086000