Full steam ahead - Scottish distillery with Grundfos

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

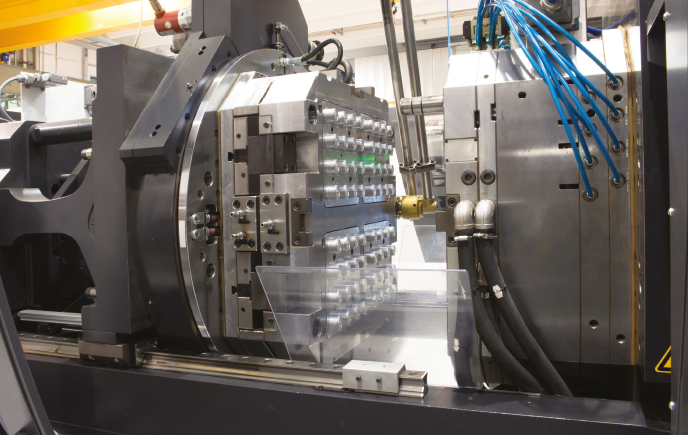

Playing it safe by over-engineering your hydraulic cylinders is not best practice. With the huge range of standard dimensions, configurations and materials available for hydraulic systems, it's perfectly possible to specify the right cylinder for the right duty, to deliver optimum performance at a competitive price, without costly customisation.

An experienced engineering manufacturer will be able to advise you on striking the right balance of the criteria below. And on doing so with standard components, to maintain effective lead times to customers.

Even for higher load requirements there’s no need for custom high-pressure designs. Tandem cylinder constructions will be cost-effective, and save compromising other areas of performance.

For customised stroke distances above 3.05m concerns grow around pressure rating. Please note, it is important to consider the positives and potential negatives to optimise system performance, the manufactures will be able to assist such requirements.

Rod diameter will need to be determined to handle the load, and if necessary a pressure rating on load in thrust (push mode) will need to be specified. However, rod sag from horizontal applications may lead to premature rod bearing wear.

When specifying speed, a rule of thumb is that standard hydraulic cylinder seals can handle speeds of up to 1m/second. The tolerance threshold of standard cushions is roughly two-thirds that speed.

A standard low-friction seal is often the better choice for higher-speed applications, but greater fluid velocity means higher fluid temperature, which may have a negative effect on the entire system. An experienced hydraulic system manufacturer will offer seals to meet a complete range of temperatures and fluid types.

Applications which require low or high temperature extremes – or both – demand expert knowledge of component interdependency, to achieve the best balance and optimum performance.

Every mounting design aims to absorb force: stabilising the system and optimising performance. Considerations when selecting a mount are load, speed, and cylinder motion (straight/fixed or pivot).

There are three basic mounting styles. Fixed and Pivot can absorb forces on the cylinder’s centreline, and typically include medium- and heavy-duty mounts for accommodating thrust or tension. A second Fixed category allows the entire cylinder to be supported by the mounting surface below the cylinder centreline.

Standardised mounts within each category meet a growing number of application requirements, and most mounting options are available for single-acting and double-rod cylinders.

Cylinder bore size is related to operating force, calculated in conjunction with system pressure requirements, and virtually every industrial requirement can be met with ISO and or NFPA standard compliant components. Piston rod size is frequently customised, but is should be remembered that push or pull is never independent of stroke length.

Standard piston rods are chrome plated, you can request other versions, stainless steel as an example, however chrome plated will suffice in the majority of applications.

Standard ISO or NFPA double-acting cylinders are supplied with ports at head and cap ends, there is an option to allow configuration, to include a four-way direction control valve to direct flow to the head or cap ends, where cylinder control be critical in the application. This is also good practice if the cylinder is located a distance away from the directional valve, to help maintain an effective hydraulic system.

There are many standard rod end options, including standard threads in metric or imperial formats, male and female and each diameter is typically available in four distinct rod-end styles. Special rod ends are available, however this introduces complexity and non-standard costs, resulting in “special product”. To maintain best engineering practice, maintain the specified thread in the opposing mating half for ease of installation.

For long stroke cylinders under compression loads, a stop tube should be used to reduce bearing stress and potential cylinder locking. Stop tubes requirements differ dependant on the style of fixing ( fixed or pivot mount ).

The stop tube lengthens the distance between rod and piston bearings, to reduce bearing load on the push-stroke cylinders when the cylinder is fully extended. This is especially critical for horizontally mounted cylinders, to increase stability and bearing life.

Some applications may require a level of customisation in component size, materials or configuration. But working with an experienced hydraulics systems solution manufacturer such as Parker, from early in the design process, can save engineering time and money through intelligent use of standard components.

Why not discover the right cylinder for your needs now, with the Parker automated cylinder quoting tool? Just visit https://ph.parker.com/gb/en/hydraulic-cylinders

Get the latest updates from ERIKS including:

Choose any or all of these via the ERIKS Subscription Centre!

Our Know+How brings together the best of the latest Know+How Hub articles in one easy to digest magazine, covering the following topics:

That's why its the leading magazine for maintenance engineers from ERIKS.

Want Know+How Magazine delivered direct to your door? Visit the ERIKS Subscription Centre to opt-in!

Take a look at our latest updates...

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

Looking for a custom Product quote? Need an answer to a Technical question? Looking for Careers/HR support? Want to work with us? Interested in our Digital Trading solutions? Have a finance question? Send us your enquiry and a member of the ERIKS team will be with you quickly.

We strive to deliver exceptional quality service and products. As part of this goal, we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

At ERIKS we strive to deliver the best quality service and products. As part of this goal we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

Call us: +441215086000