Full steam ahead - Scottish distillery with Grundfos

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

As we move towards a post-COVID world, there will undoubtedly be a greater focus on hygiene. As a result, maintenance teams at food and beverage plants, along with machinery and equipment suppliers and system integrators, must increase their efforts to avert any opportunities for contamination. Deploying a new strategy, effectively, demands a component-level approach, one in which astute bearing selection will pay a vital part with significant benefits to unlock.

For many years, the food and beverage industry has been a focus area for NSK, and to combat these increasingly important issues, the bearing manufacturer NSK continues to provide components with multiple highly-relevant design characteristics, such as corrosion-resistant materials, sealed construction and lifelong lubricants, that are all compatible with foodstuffs.

Bearing applications for food plants stretch far and wide, from raw material, to primary (cutting and mixing) and secondary (moulding), conveying, inspection, heating and packaging processes - while beverage applications focus on bottle moulding, filling, sealing and packaging. But they all have one thing in common – the requirement for high-speed, uninterrupted, hygienic operation.

To put it bluntly, continuous high-speed operation, stringent hygiene standards and demanding operating conditions call for reliable, robust bearings that facilitate cost-effective production, while optimised performance and maintenance-free operations are also essential, despite having to withstand high temperatures, excessive water and intrusive chemicals. The bearings must also prevent any potential contamination safely and reliably.

The fact truth is, your bearings have an endless list of challenges to contend with.

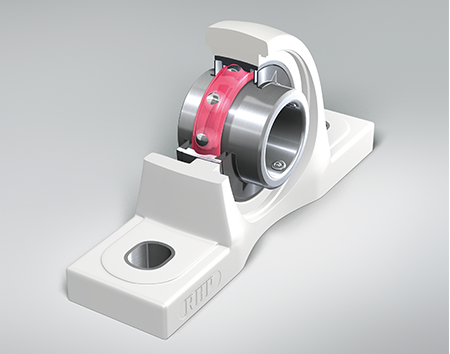

Among the core products from NSK specifically for hygiene-related applications, is the RHP Silver-Lube® range of corrosion-resistant bearing units.

Silver-Lube® units consist of bearing inserts with high-grade stainless steel rings and balls, cage, flingers and set screws, Silver-Lube® units are further enhanced with durable, heat-resistant silicone rubber seals. These inserts are located within a high-strength PBT thermoplastic housing, featuring a stainless steel grease nipple and bolt-hole liners, purposely moulded into the housing to achieve optimum hygiene.

Administered with the necessary lubrication with a wide-temperature USDA H1 food-grade grease, Silver-Lube® bearing units are designed for applications where frequent washdowns are pivotal, optimum hygiene standards are required, and good chemical resistance over a broad temperature scope is essential to production.

Available in a variety of configurations – pillow block, two-bolt flange, four-bolt flange and take-up – Silver-Lube® units are capable of accommodating initial misalignment from mounting errors.

This capability makes these bearings ideal candidates for use in food and beverage plant machinery such as shakers, fillers, centrifugal separators, bottling machines and conveyors.

Adding to the strong list of hygienic benefits, the PBT thermoplastic resin housings of the NSF-approved Sliver-Lube® bearings are paint-free, eliminating potential of chipping or flaking, while also offering an exceptional working temperature suitability from -20° to +90°C. And let’s not forget the long life capacity and low total cost of ownership.

These innovative bearing units also benefit from the sealed-for-life lubrication provided by NSK’s Molded-Oil technology. Molded-Oil is a solid lubricant, designed to not only prevent the ingress of contaminants such as water and particulates, but means that lubricant cannot exit the bearing and enter other areas of the machine, where it could potentially come into contact with foodstuffs.

As standard, the bearings are equipped with a proprietary oil-impregnated material that compromises oil and a polyolefin resin with an affinity for oil. The carrier material releases lubricant continuously over a long period, ensuring the operating environment remains clean, with the removal of any oil filling requirement.

Food facilities around the globe are turning to NSK’s innovative technology and reaping the benefits, in particular from Silver-Lube®. One as such example is a plant UK Company that harvests baby leaf produce supplied to leading supermarkets.

Previously featuring a variety of low-cost mounted-unit bearings, supporting shafts of various sizes, the plant’s leaf harvesting machine was experiencing regular failures during the all-important harvesting season caused by water and dirt ingress. This lead to avoidable downtime, production losses and, in the most severe cases, spoilt crops.

The plant proceeded to invite NSK experts to view the application and working conditions, which ultimately led to the recommendation of replacing the existing mounted-unit bearings with Silver-Lube®, featuring an innovative flinger seal arrangement and stainless steel bearings. This turned out to be an informed decision, as during the following harvesting season, only two failures occurred, leading to a significant improvement in productivity, culminating in savings of €63,300 thanks to far fewer production losses.

A UK-based milk processing plant was enduring repeated bearing failures on one of its principle conveyors, where inaccessible positioning resulted in the inability to provide re-lubrication. As a result of this frustrating occurrence, the customer was required to change the bearings every 10 weeks, at the expense of three hours downtime each time. As you can imagine this was proving rather costly, for from increased maintenance time and lost production.

Following an application review undertaken by a highly trained NSK engineer as part of the AIP Value-Added Programme, the milk processing plant decided to adopt Life-Lube® bearing units, utilising stainless steel bearing inserts charged with Molded-Oil lubrication, and fitted within corrosion-resistant polymer housings.

Offering the combination of Silver-Lube ® corrosion-resistant housing and the sealing and lubricating properties of Molded-Oil inserts in one convenient package, more notably, Life-Lube® bearings are suitable for wet and damp conditions, including those that are exposed frequently to process fluids and harsh chemicals.

Following trials on the milk processing plant conveyor, the results were truly positive, displaying a life extension from 10 weeks to more than a full year, while also removing the need to replace the shaft after each bearing failure. This cost, coupled with the labour costs associated with deploying two maintenance engineers, as well as lost production costs, achieved annual savings of over £10,000 – now that’s what you call a new lease of life!

Get the latest updates from ERIKS including:

Choose any or all of these via the ERIKS Subscription Centre!

Our Know+How brings together the best of the latest Know+How Hub articles in one easy to digest magazine, covering the following topics:

That's why its the leading magazine for maintenance engineers from ERIKS.

Want Know+How Magazine delivered direct to your door? Visit the ERIKS Subscription Centre to opt-in!

Take a look at our latest updates...

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

Looking for a custom Product quote? Need an answer to a Technical question? Looking for Careers/HR support? Want to work with us? Interested in our Digital Trading solutions? Have a finance question? Send us your enquiry and a member of the ERIKS team will be with you quickly.

We strive to deliver exceptional quality service and products. As part of this goal, we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

At ERIKS we strive to deliver the best quality service and products. As part of this goal we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

Call us: +441215086000