Full steam ahead - Scottish distillery with Grundfos

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

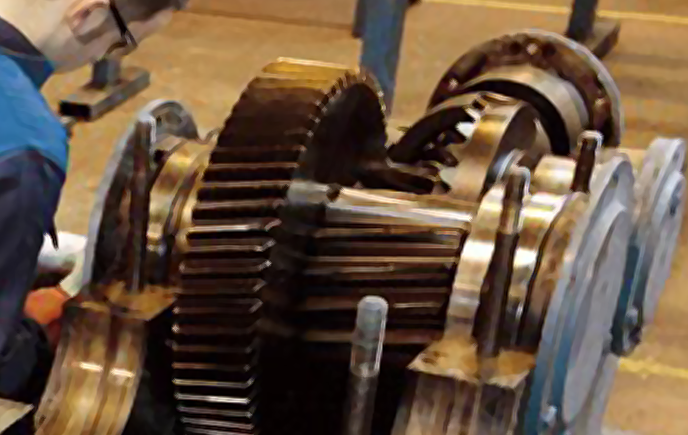

Often when equipment fails, the biggest concern is how to get it running again. However, equally as important is finding the root cause and how it can be avoided in the future. By providing managers and service technicians with the knowledge to identify causes of gearbox failures, they can establish an effective preventative maintenance program to support their plant and site operations.

Effective lubrication is critical to all gearboxes, assisting in the prevention of gear and bearing failures – many of which result from insufficient or interrupted lubrication to the drive chain.

Maintaining proper lubrication to any gearbox includes using the appropriate lubricant, keeping oil clean and free from foreign materials, and maintaining a sufficient supply to all internal operating components.

Selecting the right lubricant is based on several independent factors – gear type and style, load type, speed, operating temperature, input power and reduction ratio – so, taking into consideration the technical sophistication of today’s gearing, choosing a lubricant should be left up to a lubrication specialist to provide guidance – and ERIKS is one of those specialists, with multiple tools at our disposal for diagnosing gearbox problems.

Vibration is another key indicator in the diagnosis of machine/gearbox/equipment faults. Each fault generates a specific vibration profile, and a single vibration measurement provides information concerning multiple components.

By analysing vibration, ERIKS engineers are able to determine whether the cause of the machine fault is imbalance, misalignment, general loss of interference fits or wear, bearing or gear defects or any other unforeseen issue.

Just remember left alone, any gearbox faults can do enough damage to necessitate shutting down a piece of process equipment, making vibration analysis even more important.

While identifying the cause of gearbox failure can sometimes be as simple as looking closely at the damage, discovering root cause is considerably more difficult.

Not all companies have the sophisticated equipment required to identify vibration anomalies or analyse oil samples. Without these resources, how can they establish a preventative maintenance program?

Outsourcing preventative maintenance functions to an outside service provider such as ERIKS is certainly an option. As a specialist in preventative maintenance, ERIKS has a rich service portfolio coupled with product sourcing and supply.

Agreements and contracts can cover breakdowns, scheduled maintenance, parts reconditioning, service upgrades, reverse engineering, alignment and balancing, and on-/off-site diagnostic services. ERIKS have thoroughly skilled and trained engineers in performing gearbox root cause failure mode analysis, covering simple diagnostics to more comprehensive investigations and assessments.

While identifying the cause of gearbox failure is only the first step in establishing an overall preventative maintenance program, it’s a vital step. The information gathered will ultimately serve as the foundation for planning future preventative maintenance programmes – a necessity when working with critical equipment.

For further information, please visit contact us or call us on 0121 508 6000.

Get the latest updates from ERIKS including:

Choose any or all of these via the ERIKS Subscription Centre!

Our Know+How brings together the best of the latest Know+How Hub articles in one easy to digest magazine, covering the following topics:

That's why its the leading magazine for maintenance engineers from ERIKS.

Want Know+How Magazine delivered direct to your door? Visit the ERIKS Subscription Centre to opt-in!

Take a look at our latest updates...

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

Looking for a custom Product quote? Need an answer to a Technical question? Looking for Careers/HR support? Want to work with us? Interested in our Digital Trading solutions? Have a finance question? Send us your enquiry and a member of the ERIKS team will be with you quickly.

We strive to deliver exceptional quality service and products. As part of this goal, we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

At ERIKS we strive to deliver the best quality service and products. As part of this goal we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

Call us: +441215086000