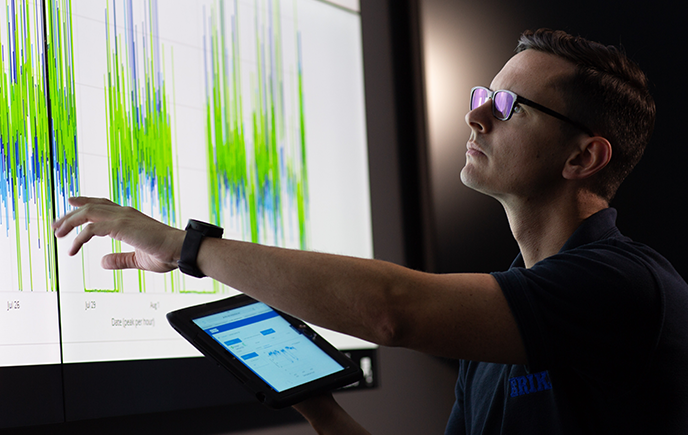

Part 2 of Making Online Monitoring part of your maintenance strategy considers the importance of gaining a holistic view of your assets to help you make a...

Continue reading...KNOW+HOW Hub

Bringing you the latest industry news, views and features, plus technology updates, comments and information.

Search Blogs, Case Studies, Events & News:

Operating in a high-production environment, one large pet food manufacturer was experiencing issues during the phase-out of their current valve manifolds on...

Continue reading...ERIKS expands in the UK with the acquisition of two sites previously operated by Parsons Peebles Group (PPG). The acquired sites in Cardiff and Derby are...

Continue reading...Part 1: Evolution, not revolution. It’s easy to promise a quick fix that reduces maintenance costs, increases uptime and efficiency, and optimises productivity. It’s much harder to make those things a reality. And anyway, in reality they’ll never be achieved with a quick fix. But using an iterative process, and with the right know-how, advice and support, making Online Monitoring part of your maintenance strategy can deliver those benefits worth waiting for.

Continue reading...It’s easy to promise a quick fix that reduces maintenance costs, increases uptime and efficiency, and optimises productivity. It’s much harder to make those...

Continue reading...Congratulations to all at ERIKS Grimsby on their donation to Viking FM's Cash for Kids charity which ensures that every child in the Grimsby area gets a gifts..

Continue reading...In asset management as in life: the more you know, the more you can do. And the sooner you know something, the better. We can't upgrade our brains. You can be smarter about your management of assets with ERIKS Smart Asset Management.

Continue reading...In asset management as in life: the more you know, the more you can do. And the sooner you know something, the better. We can't upgrade our brains. You can...

Continue reading...Overall Equipment Effectiveness (OEE) is industry’s prime metric for identifying and rectifying machinery-related problems in the manufacturing process. It’s also a benchmark for progress made against other manufacturers’ performance. But for companies lacking the necessary in-house skills, and striving to achieve more productivity for less cost, achieving the reliability and long service life that drive OEE can be challenging. A new industry-leading asset care strategy from SKF could be the answer.

Continue reading...The first task to achieve ‘No unplanned failures’ was to develop a strategic vision for reliability at the plant. Secondly, to develop an implementation plan. Lastly, to develop a reliability Best Practice document for their manufacturing group. The ultimate aims of this process would be to accelerate reliability-centred plant initiatives, mitigate risk exposure to critical spares gaps, increase productivity, obtain an insight into the assets’ status, and enable smarter replacement thanks to optimised monitoring.

Continue reading...The first task to achieve ‘No unplanned failures’ was to develop a strategic vision for reliability at the plant. Secondly, to develop an implementation plan...

Continue reading...Often when equipment fails, the biggest concern is how to get it running again. However, equally as important is finding the root cause and how it can be avoided in the future. By providing managers and service technicians with the knowledge to identify causes of gearbox failures, they can establish an effective preventative maintenance program to support their plant and site operations.

Continue reading...Never miss an update

Trends to digest in KNOW+HOW magazine

Know+How Magazine is the leading magazine for maintenance engineers from ERIKS. Missed an issue?

We explore:

- ERIKS In Action

- In Focus

- Debate

Download your copy today.

How to Contact ERIKS

Get in Touch

Looking for a custom Product quote? Need an answer to a Technical question? Looking for Careers/HR support? Want to work with us? Interested in our Digital Trading solutions? Have a finance question? Send us your enquiry and a member of the ERIKS team will be with you quickly.

How are we doing?

We strive to deliver exceptional quality service and products. As part of this goal, we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

Call us or find your local Branch

At ERIKS we strive to deliver the best quality service and products. As part of this goal we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

Call us: +441215086000