ERIKS helps Irish manufacturers' supply chain concerns

ERIKS will be exhibiting on Stand R03 at the National Manufacturing and Supply Chain Conference and ...

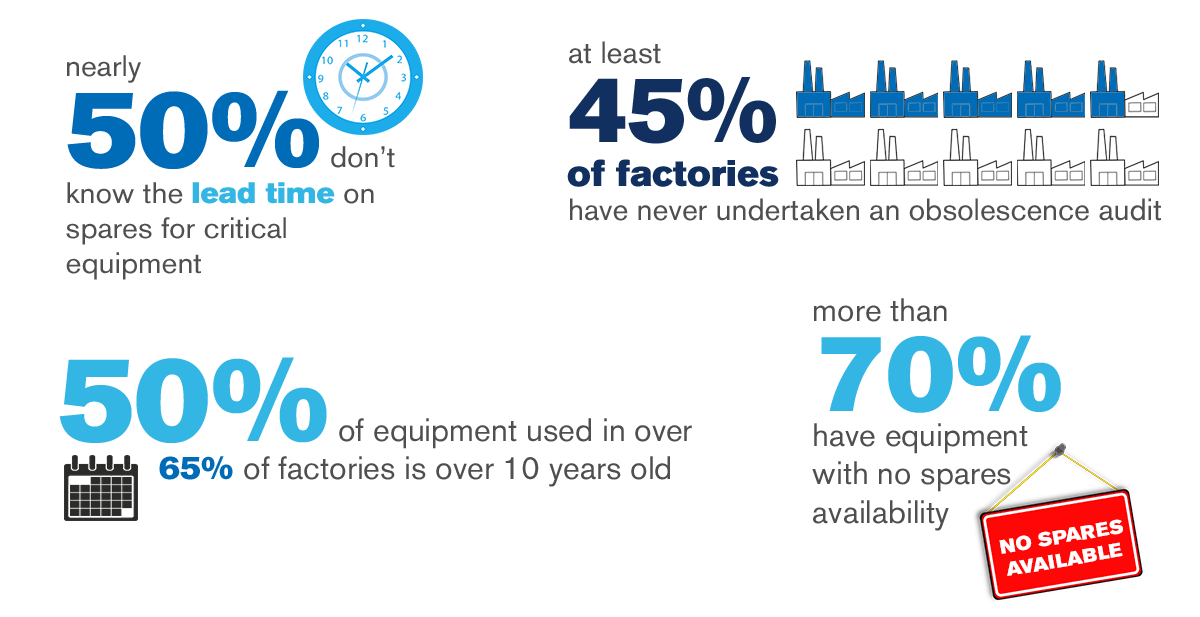

Even the most modern factories rely on maturing equipment - it is often well-made, reliable and does not need immediate replacement. Still, the word "Obsolete" presents a significant challenge for many. Thankfully, the solution lies in the management of "obsolete equipment".

NEW WHITEPAPER: Strategies for Managing and Maintaining an Ageing Asset Base

ERIKS has once again teamed up with the IET to create a new whitepaper exploring UK industry's exposure to obsolescence.

Discover current attitudes towards obsolecence, including policies and how it is being managed on the ground.

However for many companies implementing these steps requires precious resources and expertise that many companies cannot afford to spare or simply do not have.

ERIKS can do the leg work by performing a full Obsolescence Audit for you.

With our years of expertise, identifying criticality in a variety of environments comes easy to us, we can let you know which equipment is integral to your operations so you can focus on what really matters first.

When it comes to spares we know what's needed and the recommended shelf life, if it's sensible to order stock in we can tap into a wide variety of suppliers and connections for the best possible turnaround.

Finally, if spares are getting harder and harder to acquire or cannot be found, our engineers have the know-how and resources to re-engineer the perfect component to keep your plant up and running.

The new home for ERIKS News, Blogs and Case Studies - keep up to date with all the latest news and updates in one place

The latest:

ERIKS will be exhibiting on Stand R03 at the National Manufacturing and Supply Chain Conference and ...

Saving you time and money, each and every day

By impletemting ERIKS Asset Management a major drinks manufacturer was able to achieve an average MTBF of 90 months against an industry standard of 60 months.

Then you need to switch to status MONITORING from ANY/MANY locations with ERIKS e-Connect and keep up to date anytime via the cloud.

If you've got any questions or are interested in ERIKS' Obsolescence Audit offering, please use the link below.