MAKING COMPLIANCE SIMPLE

An FDA audit is a testing time – in every sense of the word – for many businesses. And even the largest businesses can find themselves falling short of requirements for FDA compliance.

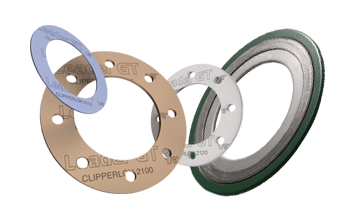

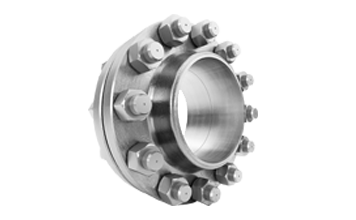

In the case of one global pharmaceutical and healthcare company, it was the manway door seals on their storage vessels which failed to meet with the FDA auditor’s approval.

Faced with the potentially tricky task of finding a suitable sealing material, given the scale of the replacement operation and the speed at which it needed to be carried out - there was only one option available.