Hygienic Power Transmission Solutions

For the average person hearing words like "gears" and "motors" can conjure up visions of oil and grime. For those within clean environments, such as food and beverage, this should be far from the case. Thankfully, there have been a number of developments making power transmissions cleaner than ever.

Did you know?

Nearly 90% of bacteria contamination, the leading cause of food poisoning, is due to poor hygienic design...

Rexnord Engineered Sustainability

Sustainability is the capacity to endure

Engineered SustainabilityTM by Rexnord is a product program to help you design durable conveyor systems with components that guarantee optimal product handling without compromising the ability to meet targets on:

- Safety improvement

- Increased productivity

- Water reduction

- Energy savings

Find out more by downloading the flyer using the button below.

Also, check out the Problem Solvers below to find an example of how Coca-Cola benefitted from the use of Rexnord's Dry-PT solution!

ERIKS Problem Solvers - Quick Solutions to Common Issues

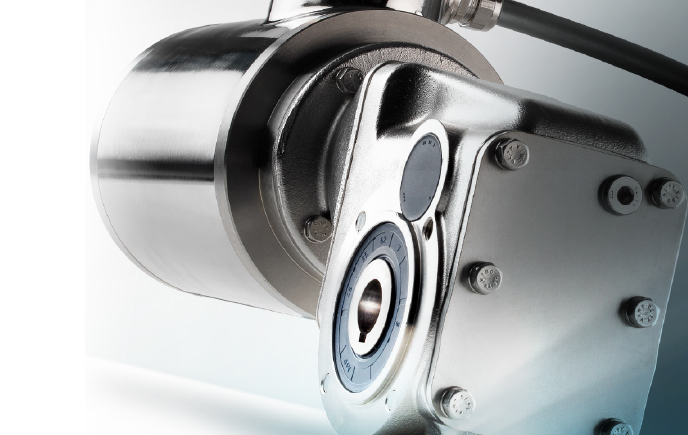

Mitigate Contamination Risk with Fenner

Following an unnannouced audit one Food and Beverage manufacturer was tasked with selecting new geared drives as their current stainless steel units did not fully mitigate the risks of contamination. Exporing their options they turned to Fenner's specially developed solution for food and beverage manufacturers.

All the Lubrication you Need

Coca-Cola was operating with an external lubrication system on a 30,000 bottles per hour PET filling line. Coca-Cola were looking to streamline the operation to eliminate additional lubrication costs and extra maintenance levels. Thanks to Rexnord Dry-PT material they could eliminate the need for lubrication all together.

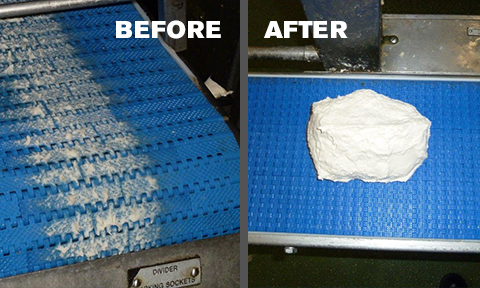

Uni-Chains Modular Belting

Fresh solutions for industrial bakeries

Designed to limit surface contact and promote reliability, the uni M-QNB NS constitutes an optimum choice for mixing and handling operations with sticky dough.

It's non-stick conveying option ensures easier product release while elminating product wastage as product detaches cleanly from the conveyor.

Find out more by downloading the flyer using the button below.

Know-How Hub

The new home for ERIKS News, Blogs and Case Studies - keep up to date with all the latest news and updates in one place

ERIKS in Action

Saving you time and money, each and every day

Contact

Get in Touch

For all general enquiries use the Enquire Online form - we'll connect you with the best member of our team for your query. Alternatively, look up your local service centre...

Got a Technical Question?

We are proud to boast a strong team of technical specialists in each of our product and service areas. If you have a technical question a member of our team would be happy to help.

Share Your Thoughts

At ERIKS we strive to deliver the best quality service and products. As part of this goal we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.