Full steam ahead - Scottish distillery with Grundfos

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

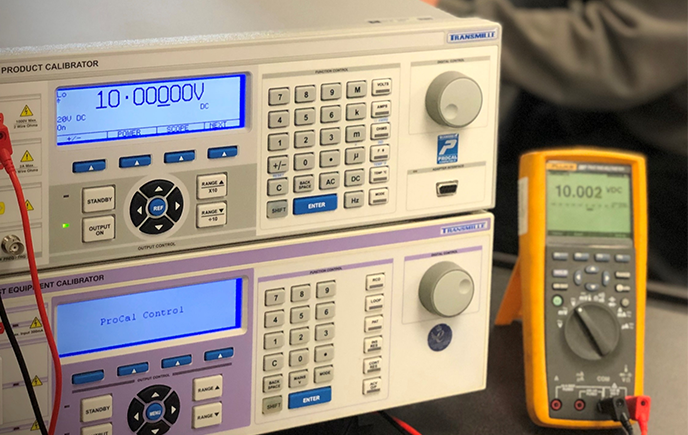

For electrical equipment to operate at its most efficient, it must perform at a minimum specification. And ensuring that specification is a task in itself. But have you ever considered that for your electrical equipment to be correctly operational, you must first check that your electrical testing equipment is up to scratch? Here’s where calibration can determine the ongoing quality, performance and limits of your instruments.

Calibration is the process in which measurements or units of unknown accuracy are compared to standards of greater accuracy. In short, calibration determines whether a manufacturer’s stated specifications are of a suitable standard. As a general rule of thumb, a 4:1 ratio is an acceptable industry standard reading.

Calibration is all about having confidence in the measurement results you receive, and to maintain confidence throughout the service life of your instruments, it’s important to undertake this process regularly.

As with a yearly MOT checks the health of your vehicle, and unearths any underlying problems, electrical testing calibration is no different. It goes without saying that the precision of your testing equipment will reduce as times goes by, simply through daily usage. For example, changes in temperature or accidentally dropping your instruments could affect the PCB and cause it to fall outside of its specification.

And you could be risking more than an inaccurate reading, if others are dependant on the accuracy of your readings when setting up other equipment. Therefore, regular health checks of your instruments are vital to ensuring maximum efficiency, performance and user safety. You could say that ‘testing the tester’ is equally important. So, with that being said, we advise to calibrate your testing equipment at least once a year, just like you would with your car or motorbike.

Unfortunately, with many businesses looking to cut costs where possible due to today’s climate, common practice for some companies is to only calibrate their testing equipment bi-yearly. We must stress that isn’t industry best practice and advise that maintaining a regular and strict regime is essential.

Tip: As simple as it may sound, consider adding a specific date to your calendar as a reminder and stick to that date yearly. Planning is essential.

Operating with any sort of electrical equipment comes with its dangers, so we advise on taking zero risks. It’s previously been reported that some companies have stuck their own calibration stickers over the original certifications to make them appear to last longer. This isn’t only not best practice, but highly dangerous for users.

With safety always a prime concern, we recommend to never operate with any electrical or testing equipment that has unofficial certification. These labels are designed to ensure users that instruments are in perfect working order and indicate the exact date on which they were last verified. To ensure maximum safety and accuracy, always check the original documentation before operating with your testing equipment.

If you would like any further information on Electrical Testing Equipment and the calibration process, please don’t hesitate to contact one of our MRO & Safety Equipment specialists on 0121 508 6000 to discuss your options.

Get the latest updates from ERIKS including:

Choose any or all of these via the ERIKS Subscription Centre!

Our Know+How brings together the best of the latest Know+How Hub articles in one easy to digest magazine, covering the following topics:

That's why its the leading magazine for maintenance engineers from ERIKS.

Want Know+How Magazine delivered direct to your door? Visit the ERIKS Subscription Centre to opt-in!

Take a look at our latest updates...

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

Looking for a custom Product quote? Need an answer to a Technical question? Looking for Careers/HR support? Want to work with us? Interested in our Digital Trading solutions? Have a finance question? Send us your enquiry and a member of the ERIKS team will be with you quickly.

We strive to deliver exceptional quality service and products. As part of this goal, we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

At ERIKS we strive to deliver the best quality service and products. As part of this goal we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

Call us: +441215086000