Full steam ahead - Scottish distillery with Grundfos

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

Challenges. We all face them, irrespective of industry. Could it be classed as a typical day in industry if we didn’t. But it’s how we analyse and overcome these obstacles that has a true bearing on our performance, productivity and, ultimately, expenditure.

Here’s where maintenance surveys can play an essential role in optimising plant reliability, increasing production capacity, improving our capabilities, all leading to driving down your Total Cost of Ownership.

Innovation is rarely accomplished alone. It requires a team with expertise, passion, and a desire for taking calculated risks in order to deliver a competitive gain. Many challenges simply aren’t clear and obvious, or easy to overcome, so thinking outside the box is often needed to get to the route of a complex problem. And this equally applies to adhesive, sealant, and functional coating solutions, particularly when considering the vast nature of application range.

Production line surveys, maintenance workshops and design seminars really add value to your business, therefore, onboarding a reputable adhesives supplier such as Henkel, owner of the LOCTITE® range, will undoubtedly be invaluable in achieving the optimum solution to attain your goals.

Now that we’ve outlined the importance of maintenance surveys, our guess is that you want to know what to expect from a full-service adhesives’ supplier?

Well, where do we start. A comprehensive production analysis service should certainly be a major part of the offering. By understanding and scrutinising the current manufacturing process, it’s possible to identify problem points, while making improvement recommendations that may not have been previously advised.

Chemical management should also be another core service. A good supplier of adhesives, sealants and coatings has the ability to monitor processes and materials to provide cost reduction solutions, improvements in overall quality, increased levels of productivity, and not forgetting environmental compliance.

The most comprehensive of suppliers may even offer some level of digital online reporting tools, allowing customers to create data extracts, build dashboards and export the results.

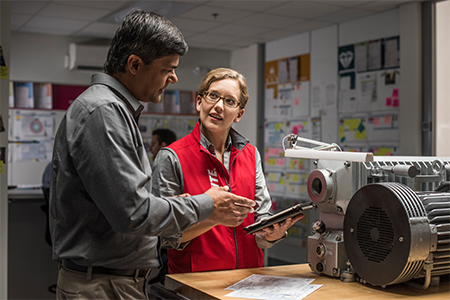

Consultation and training also form essential components of a comprehensive service. Through deploying a team of experts to assist customers in achieving their desired outcome, refining current, or even designing new, processes that are cost-effective and environmentally sustainable will enhance your current levels of productivity and reliability, thus providing a more efficient workflow.

And of course, design is a major added value in the industrial product arena, even more so in relation to cost efficiency and suitability for volume production. The best advice we can offer for those seeking expertise in design, is to select a supplier that has design centres around the globe where testing and developing customised solutions can take place. This will inevitably help reduce the costs and time associated.

Additional service provisions associated with prominent and recognised adhesives, sealants and coating solution providers such as Henkel may include maintenance and assembly services, equipment partnerships, lab testing, onsite support, sampling and prototyping, and value calculators – the latter helping to quantify the impact of a product and potential savings before committing to investment.

Over the years, Henkel has provided countless examples of how its services have assisted industrial customers in solving problems and adding value.

With a strong desire to reduce maintenance downtime, while increasing working capital and production efficiency, a globally recognised fibre cable company was seeking a solution to suit their goals. Enlisting the assistance of ERIKS, in this case, their facility in Ipswich, a proposal to involve LOCTITE® solutions was put forward, and consequently a discussion arranged between a set of engineers.

As an authorised distributor of LOCTITE® solutions, ERIKS were able to offer the customer, at no extra cost, a plant survey to target equipment failures and maintenance downtime issues. This was followed up with a range of two-hour customer training sessions in the areas identified for improvement, with focus also turning to specific product solutions, hands-on demonstrations, and implementation cycles. The free training alone saved the customer £1,250, and let’s not forget the associated future savings.

A beverage manufacturer was experiencing issues with rivet corrosion on several of its delivery trucks and was becoming increasingly frustrated with the slow and labour-intensive assembly methods, keeping engineers from undertaking more pressing matters.

The process was duly examined, and training was provided on ways in which the assembly process could be optimised using bonding with structural adhesives. LOCTITE® structural adhesives were used to completely replace the rivets on the front and rear exterior walls of each delivery vehicle instantly eliminating the corrosion issue. This new method consequently reduced assembly time by 25%.

Ultimately, a respected supplier should be able to work with customer teams to develop and optimise adhesive, sealant and automated application solutions inline with specific requirements. Whether designing a new assembly or enhancing an existing design, your adhesives partner should be able to help reduce costs and improve overall reliability.

The provision of support throughout the development cycle, including engineering assistance, adhesive development, product selection, testing, validation, cost optimisation, solution implementation, end-user training and application audits, is essential to the success of any project.

To conclude, selecting an adhesives supplier is value-based decision making in its purest form.

Get the latest updates from ERIKS including:

Choose any or all of these via the ERIKS Subscription Centre!

Our Know+How brings together the best of the latest Know+How Hub articles in one easy to digest magazine, covering the following topics:

That's why its the leading magazine for maintenance engineers from ERIKS.

Want Know+How Magazine delivered direct to your door? Visit the ERIKS Subscription Centre to opt-in!

Take a look at our latest updates...

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

Looking for a custom Product quote? Need an answer to a Technical question? Looking for Careers/HR support? Want to work with us? Interested in our Digital Trading solutions? Have a finance question? Send us your enquiry and a member of the ERIKS team will be with you quickly.

We strive to deliver exceptional quality service and products. As part of this goal, we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

At ERIKS we strive to deliver the best quality service and products. As part of this goal we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

Call us: +441215086000