Full steam ahead - Scottish distillery with Grundfos

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

In our lifetime, many of us wouldn’t have experienced such a crisis as Covid-19. It’s truly unknown and having devastating consequences not just in the UK but across the globe. Now, more than ever, is time for us all to dig deep, work in unison and support each other wherever possible.

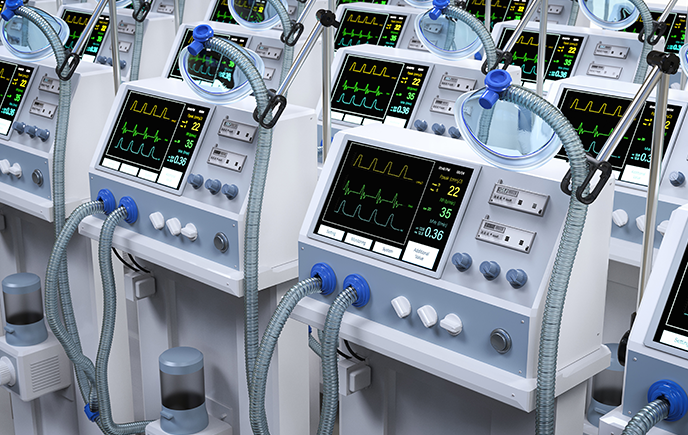

The UK Government recently declared a state of emergency, and pressure continues to grow to on our National Health Service. Pressure that has far exceeded anything for decades. To assist with the struggle, major manufacturers and suppliers are being requested to support during these challenging times, with ventilation systems at the peak of the wish list.

Demand is at an all-time high. To put it into perspective, an NHS official suggested that the UK would need approximately 30,000 ventilators to cope with the height of the pandemic, but only had access to 6699 adult and 750 paediatric ventilations systems. The difference in figures is worrying, but with the help of blue-chip manufacturers and suppliers, the pressure could be significantly reduced. And ERIKS was more than happy to offer support when called upon.

The Government Consortium reached out to ERIKS to support in sourcing products to build a range of ventilators. ERIKS are the incumbent supplier of two small O-rings for the design in question, and following discussions with the Consortium, a request to supply 8,000 of each design was submitted.

Quickly understanding the demand and urgency of the situation, ERIKS Sealing and Polymer utilised its strong, extensive supply chain and transported stock into the UK from Alkmaar, Holland, to ensure that these components could immediately ship from stock to meet the demand of building 174 units per day.

Obviously, ERIKS were happy to support the consortium, delivering at the standard commercial rate, despite additional logistics costs.

ERIKS were contacted via Linkedin for help with an enquiry for a further 30 O-rings, bearings, silicone tubing and adhesives, an order that was initially placed with another incumbent supplier. Time was clearly of the essence, as ERIKS worked to establish the many new supply chains, for what in many cases were non-catalogue items. It became evident that to hit the drop-dead delivery date and support the UK’s efforts to manufacture ventilators, immediate order placement was essential.

An executive decision was made to pre-empt the request, and parts were sourced and ordered. Quick thinking and our flexible supply chain prevailed, and most parts were delivered to the UK from Holland, Belgium and Italy, ready for immediate dispatch.

In addition, certification and accreditation were confirmed for any new material grades and one compound was specifically developed and introduced, along with allocating data sheets and establishing part numbers, to ensure all components were compliant with strict regulations. Afterall, for such an important application, everything needed to be exactly as requested.

It was later advised the other incumbent supplier could not deliver several of the required items, so with less than 24 hours to deliver the order, it was placed with ERIKS.

All the preparation work paid off, but the consortium needed extensive bagging and sorting to help them get the parts to the correct assembly locations. Normally, this process would take place at the Barnsley Service Centre using automated equipment. But its time sensitive nature left no room for transport across the country.

Items needed to be bagged, tagged and labelled at 40, 80 or 160 pieces per package. At 40 per bag, that would have meant 200 bags for the complete 8,000 pieces. So, you can appreciate the time and concentration levels required for such a crucial part of the process. The logistics team at our Dudley Distribution Centre stepped forward and worked late into the night to prepare the goods for dispatch.

But one of the parts needed was a non-standard O-ring and impossible to acquire stock in time, once again threatening severe delays in delivery, perhaps up to three weeks. The Consortium asked for a ‘miracle’. Cue ERIKS’ Warrington Technology Campus.

It was all hands-on deck for the team at Warrington, who began CNC manufacturing moulding tools to start production. Volume orders had been placed, but due to the urgency, the gap in the supply chain needed filling in the interim, until stocks arrived. 8,000 units needed to be manufactured and quickly.

This process is particularly complex, and in normal circumstances would take several weeks. But working into the early hours of the next morning, 10 O-ring tools had been produced and 200 parts moulded, post-cured and de-flashed, ready for collection by the courier, hot off the press.

The work undertaken behind the scenes in such a short time frame was truly remarkable, involving the Service Centre, Distribution Centre and Business Unit teams. Adopting a strong work ethic and teamwork mantra, along with utilising our extensive supply chain and showcasing the flexibility of the ERIKS network, enabled the request to be processed, manufactured and delivered on time for Rolls Royce production to commence on 8th April 2020.

A large volume request for LOCTITE products, various metals and glues was also part of the order, a request which other ERIKS divisions quickly processed.

In a time when our country needed our help, ERIKS proudly stepped forward and delivered on our promises, and those of others.

Get the latest updates from ERIKS including:

Choose any or all of these via the ERIKS Subscription Centre!

Our Know+How brings together the best of the latest Know+How Hub articles in one easy to digest magazine, covering the following topics:

That's why its the leading magazine for maintenance engineers from ERIKS.

Want Know+How Magazine delivered direct to your door? Visit the ERIKS Subscription Centre to opt-in!

Take a look at our latest updates...

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

Looking for a custom Product quote? Need an answer to a Technical question? Looking for Careers/HR support? Want to work with us? Interested in our Digital Trading solutions? Have a finance question? Send us your enquiry and a member of the ERIKS team will be with you quickly.

We strive to deliver exceptional quality service and products. As part of this goal, we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

At ERIKS we strive to deliver the best quality service and products. As part of this goal we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

Call us: +441215086000