Full steam ahead - Scottish distillery with Grundfos

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

Imagine you've been feeling under the weather and you're not sure why. You take yourself to the doctor's and you're offered a choice of diagnostic techniques: Investigate surgery or blood analysis? When a hydraulic system is not performing as it should be, and components are failing prematurely or frequently, those are effectively the options. So do you choose to put your system under the scalpel, or do you reach for the syringe instead?

An estimated 70% of component replacement is due to surface degradation or wear. In hydraulic and lubrication systems, half of those replacements are down to mechanical wear, and a fifth to corrosion. Yet both those problems can be picked up by oil analysis – often well before the problem turns into a crisis.

So your assets not only avoid being dismantled for “investigative surgery”, but can be “treated” without the need for a major operation.

There are essentially four types of oil contamination (see below), and each one can cause different problems within the system. The only thing they have in common is that each one is bad news.

But simply identifying their presence is not enough. The results of the oil sample need expert interpretation to pinpoint the root cause of the contamination, so you can take steps to resolve it.

That’s why ERIKS’ independent laboratory oil analysis service goes beyond simple sampling and reporting. It also includes comprehensive and expert analysis by a qualified Application Engineer.

A less useful analysis may only tell you what’s in the oil that shouldn’t be. An ERIKS analysis will not only discover the contamination, but will also identify the likely source, and propose the most effective solution.

For example, dust in the oil can be countered by installation of desiccant breathers, to prevent ingress of dust or other small particles.

Water is another common oil contaminant, with a number of potential sources. In a hygienic environment, ingress during aggressive high-pressure washdowns could be the cause.

If your power packs become very hot, water in the oil could be condensation. Or there may be a leak into the hydraulics from the cooling side of the system.

ERIKS’ experts will know what to look for, where to look, and can either guide your engineers or inspect the system for you, before addressing the root causes of the problem.

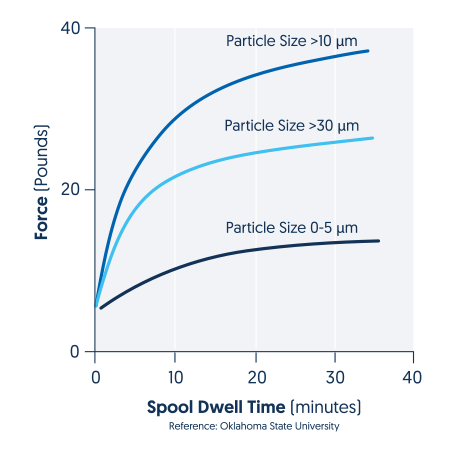

If you adhere to the ISO Cleanliness Code, you may be thinking that dirty oil isn’t something you have to worry about. Unfortunately, that’s not the case.

Every hydraulic component has an ISO code to guide you on the level of filtration required. But cracking the code and choosing the correct filtration depends on a number of variants, including the system operating pressure and the particular components within the system. In fact there could be a number of different codes and a number of conflicting filtration levels indicated for one system, leaving you none the wiser about which to choose.

ERIKS’ expert Application engineers are able to advise you on the correct code to observe and the right filtration rating to adopt, to ensure the optimum service life for all components within your hydraulic system.

So after hydraulic oil analysis by ERIKS, you can expect:

If it’s possible to squeeze out that much essential information from a few drops of oil, surely it’s time to learn the truth about your own hydraulic system? Especially when the process is as simple as taking a sample.

The 4 basic types of oil contaminants are:

Reliability is a buzzword that is seemingly always on the tip of industry tongues, but it’s clear that businesses need to be more proactive in their attempt to maximise their assets.

In this issue, we look beyond equipment, but at processes, systems, strategy and communication.

Get the latest updates from ERIKS including:

Choose any or all of these via the ERIKS Subscription Centre!

Our Know+How brings together the best of the latest Know+How Hub articles in one easy to digest magazine, covering the following topics:

That's why its the leading magazine for maintenance engineers from ERIKS.

Want Know+How Magazine delivered direct to your door? Visit the ERIKS Subscription Centre to opt-in!

Take a look at our latest updates...

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

Looking for a custom Product quote? Need an answer to a Technical question? Looking for Careers/HR support? Want to work with us? Interested in our Digital Trading solutions? Have a finance question? Send us your enquiry and a member of the ERIKS team will be with you quickly.

We strive to deliver exceptional quality service and products. As part of this goal, we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

At ERIKS we strive to deliver the best quality service and products. As part of this goal we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

Call us: +441215086000