Full steam ahead - Scottish distillery with Grundfos

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

Just like cigarettes come with health warnings, perhaps some air filters should come with a ‘wealth warning.’ Because by simply changing your filter to a different type of technology, you can reduce your energy costs while maintaining a sufficient level of filtration and airflow.

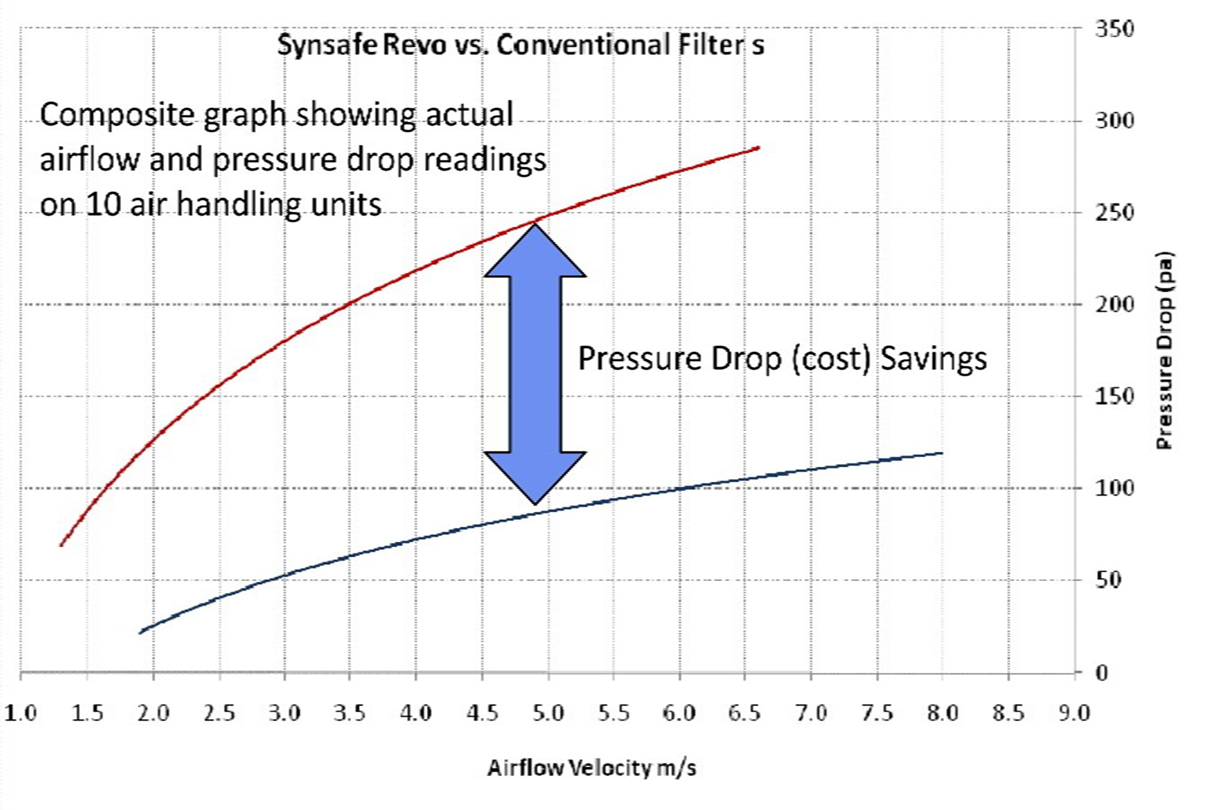

Whether you are using an air filter as part of your process or to maintain an environment, you face the same problem of maintaining an acceptable balance of filtration efficiency and back pressure.

The higher the filtration efficiency, the higher the initial back pressure, and the sooner the filter becomes clogged. In both cases, reduced air flow leads to higher energy use, due to the fan having to work harder or run faster to push the air through the filter.

Over the years, developments in filter technology have largely been aimed at achieving acceptable filtration levels without increasing back pressure or shortening filter life through faster clogging, and without increasing energy consumption through the need of a more powerful or faster fan.

One way to ensure this is to increase filter surface area – providing exceptionally low pressure drop – combined with high filtration efficiency and a high dust-holding capacity. This technology is now commercially available in the form of the Vokes-Air Synsafe Revo filter, which combines two advances in filtration technology.

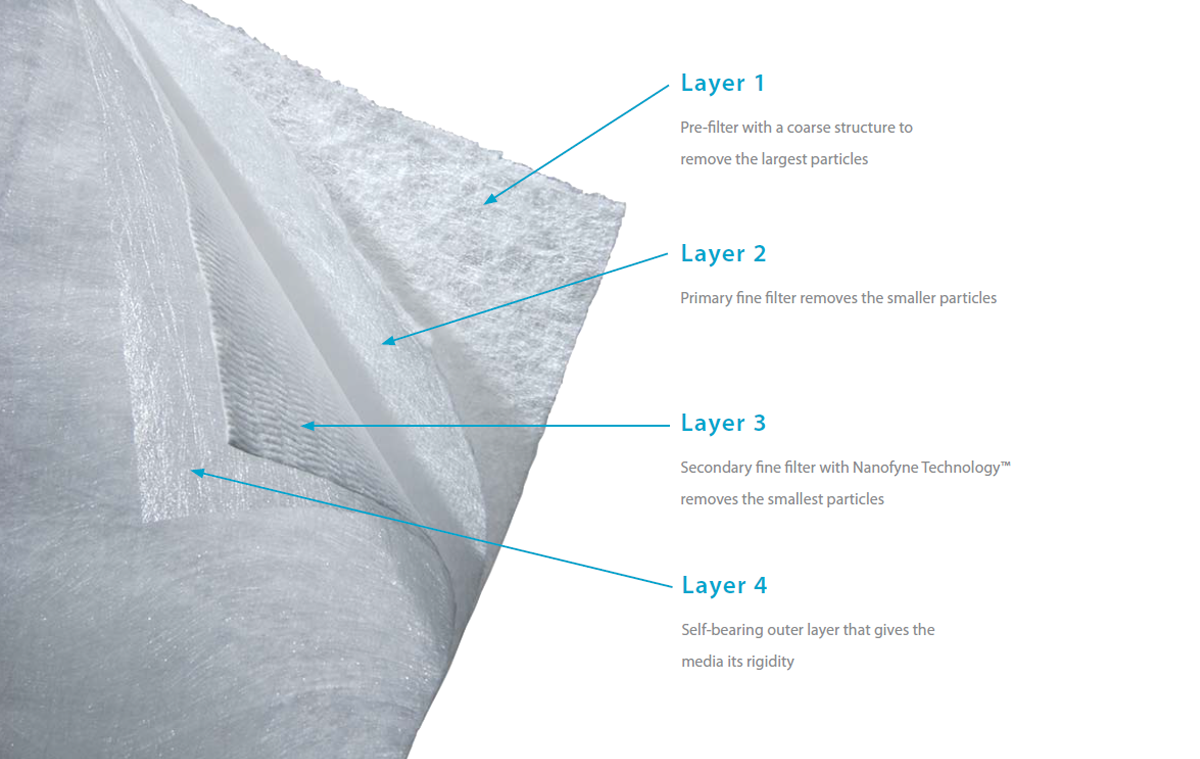

Firstly, it utilises not one but four progressive filter layers. This not only means that a greater dust-holding capacity is available, but also ensures the filters have a longer life before the build-up of filtered particles increases and reduces efficiency to unacceptable levels.

The four layers comprise of:

Secondly, the filters in the Synsafe Revo are made from nano fibres, using unique Nanofyne technology. These fibres have a diameter of less than 1μm (compared with 3μm for fibres in conventional filters), which means they offer a greater fibre surface area for trapping dust, together with less density to create back pressure.

The result is higher filtration efficiency and a longer, lower pressure drop, which means the fan is operating at a lower speed, consequently using less energy.

If the fan is belt driven, then this will provide the opportunity for a change of belt and pulley ration to reduce the fan speed, or an inverter to provide speed control – both areas in which ERIKS can provide expert advice and assistance.

Want to know more? Visit eriks.co.uk or call 0121 508 6000 to speak with one of our highly trained technicians.

Get the latest updates from ERIKS including:

Choose any or all of these via the ERIKS Subscription Centre!

Our Know+How brings together the best of the latest Know+How Hub articles in one easy to digest magazine, covering the following topics:

That's why its the leading magazine for maintenance engineers from ERIKS.

Want Know+How Magazine delivered direct to your door? Visit the ERIKS Subscription Centre to opt-in!

Take a look at our latest updates...

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

Looking for a custom Product quote? Need an answer to a Technical question? Looking for Careers/HR support? Want to work with us? Interested in our Digital Trading solutions? Have a finance question? Send us your enquiry and a member of the ERIKS team will be with you quickly.

We strive to deliver exceptional quality service and products. As part of this goal, we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

At ERIKS we strive to deliver the best quality service and products. As part of this goal we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

Call us: +441215086000