Full steam ahead - Scottish distillery with Grundfos

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

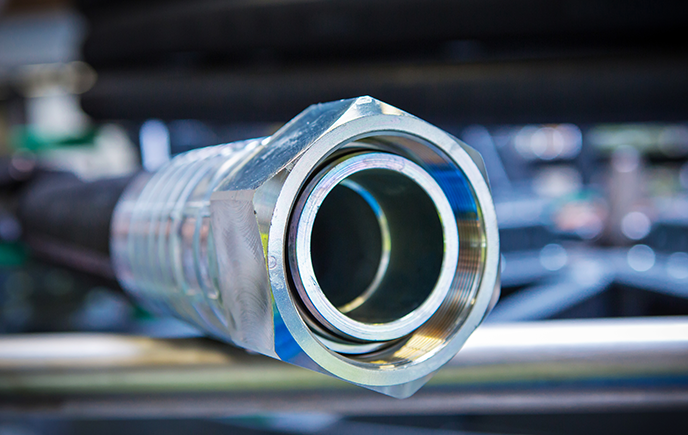

You can get more out of your industrial and hydraulic hose than fluids and hydraulic oil. When they’re correctly specified, monitored and maintained, you can also get longer life, greater efficiency, higher productivity and lower total cost of ownership.

Although it’s a fact that is often overlooked – like the hoses themselves – hoses are assets like any other. And like any other, they repay proper asset management in a number of ways. The key is not to treat them as an afterthought, but to ensure they have specialist care from experts. Like the kind of care and maintenance provided by ERIKS Fluid Power, Transfer and Control Hose Integrity Management service.

Across the whole range of hose applications – chemicals, air, food and beverages, and hydraulic oils – the ERIKS Hose Integrity Management Service helps you to maintain your existing hoses, identify reasons for failure, repair, replace, test and validate your hoses, and otherwise manage your hose assets in every way, for optimum return on investment.

It’s impossible to manage your hoses if you don’t know what and where those assets are.

That’s why the first stage of engagement for ERIKS’ hose maintenance services is an identification of all hose assets on your site. This will be used to create a hose registry containing full details of all industrial and hydraulic hoses, including their location and type. With all hoses on site barcoded, QR coded or RFID tagged, once the registry has been completed it can be used as the basis for a comprehensive cloud-based digital database.

This makes it easier for all those involved at a local level – from Maintenance Engineers to Plant Directors and even Procurement – to access the complete hose inventory via any smart device, identify any hose on your site, and see its full specification.

With all your hose assets identified, the next step is to establish their current condition. This inspection takes different forms for industrial and hydraulic hoses.

Ensuring your industrial hoses are fit for purpose and compliant with all relevant legislative requirements demands thorough, comprehensive, periodic hose inspections. ERIKS Hose Integrity Management Service provides for on-site inspection at least annually, depending on the hose criticality and your KPIs.

The inspection comprises of a:

Following the inspection, our engineers will advise of hose condition, and offer a replacement hose for those which have an issue. All inspection and test results will be recorded on the hose asset registry for future reference.

A thorough external inspection of your hydraulic hose assemblies, with the hoses assessed against set criteria, will identify any problems or potential problems. Hoses which require replacement will be identified with a red tag, while hoses which are considered in good enough condition to operate safely until the next annual inspection will be tagged with a green tag.

The visual inspection will take into account:

You will then be quoted a price for replacement of red-tagged hoses, which can be installed immediately from stock held on the engineer’s vehicle. Complete assemblies can also be manufactured on site if required.

A safety review will also be carried out at the same time, assessing your hydraulic hose assemblies in line with current British Fluid Power Association best practice for hose routing etc.

By carrying out regular scheduled expert inspections of your industrial and hydraulic hose assets – and replacing hoses when issues are identified – the ERIKS Hose Integrity Management Service will ensure that your hoses are always compliant with all relevant legislation. Our engineers will also advise on whether any hose assets not originally supplied by ERIKS meet COMAH regulations for safe operating on site and meet the required EN or ISO specifications. If not, we will recommend replacement as soon as possible.

Failure of any hose will have some impact on productivity. Failure of a hydraulic hose in particular could have critical safety implications if, for example, oil under pressure is released: risking operator injury or product contamination.

ERIKS can help you to predict and prevent failure, by identifying failure modes and looking for repeat patterns. The engineers can then make recommendations to avoid further failures: whether that’s an alternative hose or hose assembly, or employee education and training to reduce hose wear and tear from mishandling.

The result will be less hose-related downtime, longer hose life, and a lower total cost of ownership of all your hose assets. The sooner you take advantage of ERIKS Hose Integrity Management Service, the sooner you can expect to see all those benefits coming down the pipeline.

Get the latest updates from ERIKS including:

Choose any or all of these via the ERIKS Subscription Centre!

Our Know+How brings together the best of the latest Know+How Hub articles in one easy to digest magazine, covering the following topics:

That's why its the leading magazine for maintenance engineers from ERIKS.

Want Know+How Magazine delivered direct to your door? Visit the ERIKS Subscription Centre to opt-in!

Take a look at our latest updates...

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

Looking for a custom Product quote? Need an answer to a Technical question? Looking for Careers/HR support? Want to work with us? Interested in our Digital Trading solutions? Have a finance question? Send us your enquiry and a member of the ERIKS team will be with you quickly.

We strive to deliver exceptional quality service and products. As part of this goal, we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

At ERIKS we strive to deliver the best quality service and products. As part of this goal we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

Call us: +441215086000