Full steam ahead - Scottish distillery with Grundfos

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

The winter, where do we start. It’s the one time of year that most of us would prefer to skip, mainly because it gives us the shivers. But unfortunately, we all must grin and bear it, and do our best to overcome the obstacles that it presents.

When it comes to your hoses, the sudden changes in temperature can cause endless issues, but planning ahead and introducing the right type of hoses for the environment is vital to ensuring maximum efficiency for your facility and safety for your employees.

Traditionally, steam hoses are manufactured from EPDM, a common compound used in industry. But under examination this poses multiple issues when analysing your steam hoses and systems.

Firstly, under microscopic conditions, EPDM is a very porous substance. This means that when you depressurise your hoses, the steam that runs through the inside condenses and turns into water vapour, which then proceeds to sit in the well of the hose and absorb into the pores and pockets of the lining. Upon recharging your hose, the steam rapidly expands leading to explosion causing what is known as pop-corning and blistering, and we can tell you that’s not a good sign.

Little bits of rubber compound are then released into the steam system, which will have significant impacts on plant maintenance. Swelling will then occur, restricting the flow of steam through your hoses, reducing their efficiency.

All these factors then lead to reduced lifecycles of your hoses, resulting in expensive time and costs associated with maintenance, replacement, repair and so forth.

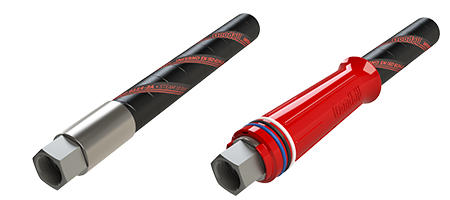

Now we’ve discussed the problems with EPDM, we’ve got some good news for you, and it’s called Goodall Inferno - arguably amongst the very best steam hoses in the world. Tried and tested to the most rigorous standards, it has proven time and again its ability to cater with the most arduous environments in industry.

At first glance there are noticeable differences – yes, it’s black as opposed to the red variations which have flooded the UK market in recent years. But that’s simply not for aesthetic purposes. Unlike the far less effective red hose types, Goodall Inferno hoses are produced with a black liner and cover, filled with conductive properties which allow for anti-static conductivity of static charge to flow to earth safely, reducing the risks of static discharge which could ignite in a flammable atmosphere.

Goodall Inferno hoses, which exceed ISO 6134-2A, are chlorobutyl lined, meaning that under microscopic conditions they are far less porous, reducing the chances of pop-corning and blistering, as the water that sits in the pores of the hose is eliminated.

Galvanised reinforcement is another advantage of Goodall Inferno hose. This reduces the risk of any corrosion of the internal braided reinforcement migrating along the length of the hose and damaging its integrity. Historically this is a huge problem area, as you are unable to see the damage as its sandwiched in between two layers, and your hose could pop at any moment, without prior warning. Therefore, operating with a galvanised reinforced structure significantly reduces the risk of serious injury.

Generally speaking, hose manufacturers make hoses, and coupling manufacturers produce couplings, but what makes Goodall so unique is the fact that they create the full system, with hose and couplings purposely designed to work in unison.

The quality of the Goodall steam hose and DuraCrimp coupling range isn’t left to chance. They are placed through rigorous 1000-hour steam endurance tests, prescribed by MIL-DTL-29210, tested using saturated steam.

Highly suitable for applications that including heating steam, cleaning steam and process steam, the Goodall Inferno and DuraCrimp solution is particularly effective in, but not limited to, industries such as chemical and petrochemical, paper and glass, steel, energy and packaging.

In addition, systems come with a range of fitting options including: 3-piece coupling, male thread, swivelling female thread BSP, loose or fixed flanges, handles with colour coding. Whatever you need to suit your application, the Goodall range has you covered.

As you know, handling steam applications comes with its hazards. But Goodall steam hoses and DuraCrimp coupling systems are purposely designed with safety at the core. Built with a robust structure and anti-kink properties to reduce risks, connections are totally leak-proof.

Operator safety is also achieved through the well-designed ergonomic handle that increases protection against heat when hoses are required to be handheld.

Finally, the range of steam hoses comes with colour coding and integrated RFID chip capabilities for easy identification.

Not only are the safety and ergonomic benefits great, but there are excellent financial gains to be snapped up by using Goodall Inferno and DuraCrimp coupling system.

Essentially, the cost of lost steam can be very high, damaging the bottom line of your business. But these huge cost losses can easily be avoided by implementing the right steam system for your application.

We must stress that this is only an example, and more accurate figures can only be calculated based on your personal plant regime, but industry research has suggested:

Taking those average figures into consideration, you could potentially be at a cost loss of £5489.80 per year per leaking coupling, assuming you have your steam hose charged over the winter months only, for longer durations of steam hose use, the cost is clearly a lot higher. Now think of it this way. If you have 10 leaking steam couplings on your site, that equates to more than £50,000 of avoidable cost loss, not to mention the maintenance costs associated with staff needing to walk your plant to tighten up loose bolt clamp-style clamping methods. Have we got your attention now?

To summarise, Goodall steam hoses and DuraCrimp system are built on three core principles – safety, savings and sustainability - increasing user safety, offering 3x extended service life leading to lower TCO and less product waste reducing impacts on the environment.

Let’s leave you with a simple sum: Goodall Inferno steam hose + DuraCrimp crimping system = the most reliable solution for your steam applications.

If you would like to know more please contact one of our Steam Hose specialists on 0121 508 6000 or why not download our Goodall Inferno Steam Hose brochure by simply CLICKING HERE.

Get the latest updates from ERIKS including:

Choose any or all of these via the ERIKS Subscription Centre!

Our Know+How brings together the best of the latest Know+How Hub articles in one easy to digest magazine, covering the following topics:

That's why its the leading magazine for maintenance engineers from ERIKS.

Want Know+How Magazine delivered direct to your door? Visit the ERIKS Subscription Centre to opt-in!

Take a look at our latest updates...

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

Looking for a custom Product quote? Need an answer to a Technical question? Looking for Careers/HR support? Want to work with us? Interested in our Digital Trading solutions? Have a finance question? Send us your enquiry and a member of the ERIKS team will be with you quickly.

We strive to deliver exceptional quality service and products. As part of this goal, we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

At ERIKS we strive to deliver the best quality service and products. As part of this goal we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

Call us: +441215086000