Full steam ahead - Scottish distillery with Grundfos

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

How do you take control of your process pipeline fluids, gases, slurries and powders, without risking contamination? In the food and beverage sector, increasingly the answer is pinch valves.

Diaphragm, ball, butterfly and needle valves are the traditional options. But when there's an equally hygienic solution, that's even simpler to install and use, and more cost-effective, why wouldn't you try it? Especially when there are three variants to meet different requirements, all conveniently available from one supplier.

In food and drink processing, keeping the media separated from the valve is essential to prevent contamination. In some industries the opposite is true: it's the valve which needs protection from media such as solvents, glues or aggressive chemicals.

But in both cases, the pinch valve is a practical and simple solution, with several advantages over more complex technologies. Not least of which is the straight-through flow it offers, with very little pressure drop over the valve, and minimal volume loss when transitioning between batches.

The pinch valve's simplicity also eliminates dead volume, where fluid can be trapped and become a potential contamination source. And of course, its simple design reduces downtime for fitting, tubing changes and valve replacement.

While all types of pinch valves share a set of underlying common principles, manufacturers focusing on one types alone limit end-user's options. That's why IMI Norgren offer a choice of three: Solenoid, pneumatic and proportional, each bringing specific benefits.

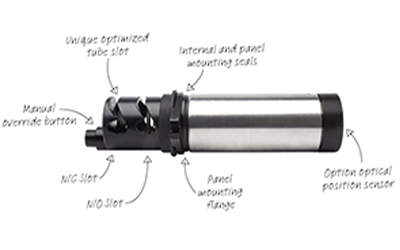

The IMI Norgren VersagripTM Solenoid Pinch Valve is a patented solenoid-actuated valve, designed for fast operation, easy tube loading and unloading, and a secure hold on the tube during valve actuation.

In many processes, speed of valve closure is crucial. So, a pinch valve with an average actuation speed of 80 milliseconds or less with an unloaded tube could be the quick answer.

By specifying the tube you are using, IMI Norgren will be able to recommend the pinch valve that meets your requirements. For optimum performance add-ons such as a solenoid controller option, manual overrides and digital feedback sensors are also available.

Panel mount-ready and with seals that make cleaning and sterilisation easier by preventing liquid ingress during wash-down, the VersagripTM is a flexible, affordable valve.

For controlling higher pressures however, the pneumatic pinch valve is the answer. Pneumatic pinch valves can be actuated with a much higher pinch force than the solenoid variants.

Robust and reliable, compact pneumatic pinch valves from IMI Norgren feature panel splash seals for wash-down and are available in an aluminium housing with a black acetal head (Acro M600 Series), black idonsied aluminium or 306L stainless steel (Acro M900 Series).

The Acro M600 Series offers three models for lower volume flows at media pressures typically up to 60psi. The pinch gap is adjustable for use with optimised tube sizes, and options include valve state detection sensors and 3 or 4-way controllers for pressure venting between states.

For still higher pressures, the M900 Series Pneumatic Pinch Valves can handle media up to 75psi and work with harder or larger diameter tubing which requires a stronger pinch force.

They can be set up normally open or normally closed default states and options include 3 or 4-way controllers, valve state detection sensors and manual overrides.

Solenoid and pneumatic pinch valves are the most practical and efficient solution for fully on or fully off flow control applications. But what if you want more flexiblity? Then there's the IMI Norgren PE900 Proportional Pinch Valve.

Flexible and adjustable, the PE900 completes the IMI Norgren Pinch Valve line-up, and proves that whatever critical fluid you ahve that needs hygienic handling, you only need to talk to one manufacturer.

Sounds like a dream? Pinch yourself

Get the latest updates from ERIKS including:

Choose any or all of these via the ERIKS Subscription Centre!

Our Know+How brings together the best of the latest Know+How Hub articles in one easy to digest magazine, covering the following topics:

That's why its the leading magazine for maintenance engineers from ERIKS.

Want Know+How Magazine delivered direct to your door? Visit the ERIKS Subscription Centre to opt-in!

Take a look at our latest updates...

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

Looking for a custom Product quote? Need an answer to a Technical question? Looking for Careers/HR support? Want to work with us? Interested in our Digital Trading solutions? Have a finance question? Send us your enquiry and a member of the ERIKS team will be with you quickly.

We strive to deliver exceptional quality service and products. As part of this goal, we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

At ERIKS we strive to deliver the best quality service and products. As part of this goal we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

Call us: +441215086000