Full steam ahead - Scottish distillery with Grundfos

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

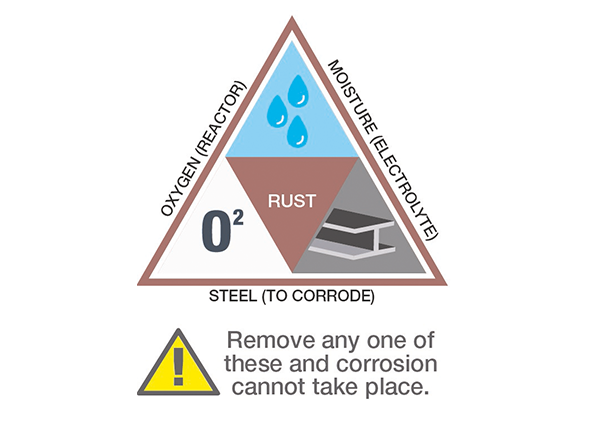

Corrosion is an ever-present problem for all ferrous metals, there are many methods to guard against it. ERIKS and Ambersil aim to demystify zinc and zinc-like coatings.

Different anti-corrosion coatings are selected to fulfill application-specific criteria, but all can be braodly categorised as either

Within these two categories, there are many products - manily in the barrier type - and all can be categorised as either "short term temporary" or "long-term permanent".

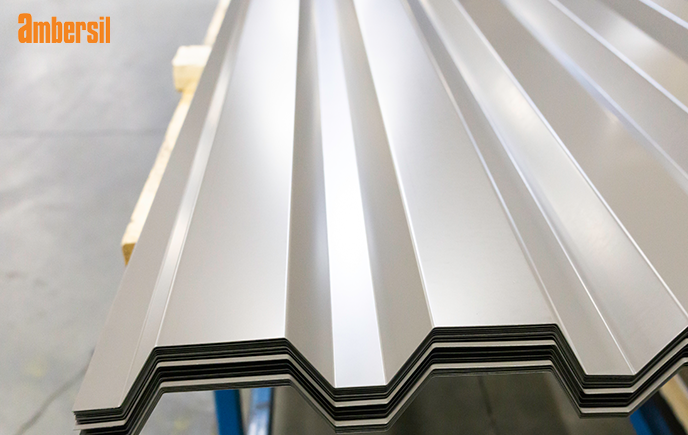

At the top end of the protection spectrum, molten zinc is used in the hot-dip galvanising process that physically bonds zinc to a steel substrate.

The process provides exceptional protection to the steel not only because the steel is entirely covered by a barrier of zinc - isolating it from rain, salts and corrosive elements - but also, because zinc corrodes in preference to the steel, providing either cathodic protection.

The 'cathodic protection' that the zinc provides is a weak electromechanical current to the steel, restricting the ionic exchange in the corrosion process.

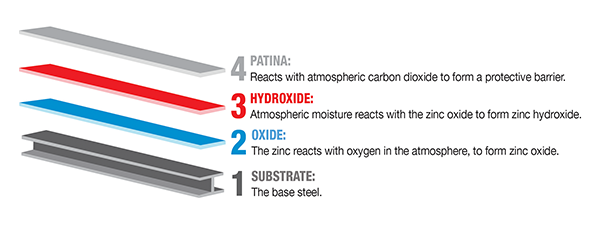

As the zinc corrodes - in preference to the steel - it forms zinc oxide then (In the presence of moisture - a zinc hydroxide patina which further protects the steel. This sacrificial process continues until the pure zinc has reacted, at which point the steel begins to corrode.

When taling about zinc and zinc content, it is important to understand the different types of zinc and the performance characteristics of each:

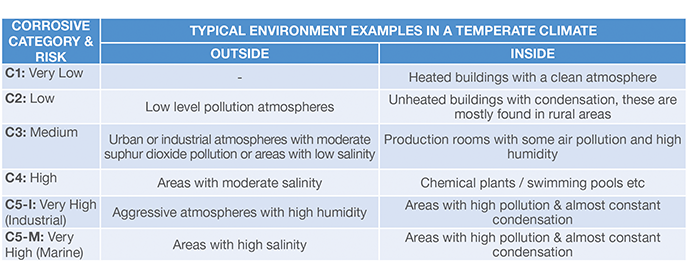

All coatings can be tested to standardised methods detailed in ISO 9227 & ASTM B117 (salt and spray test). The results of these tests indicate the performance of a coating under laboratory conditions, in an aggressive/accelerated process. In order to bridge the gap between laboratory conditions and real world performance, ISO 12944-2 categorises product based on sustainability for specific environmental conditions: from C1 to C5 (marine). Many aerosol pack coatongs fit into category C3.

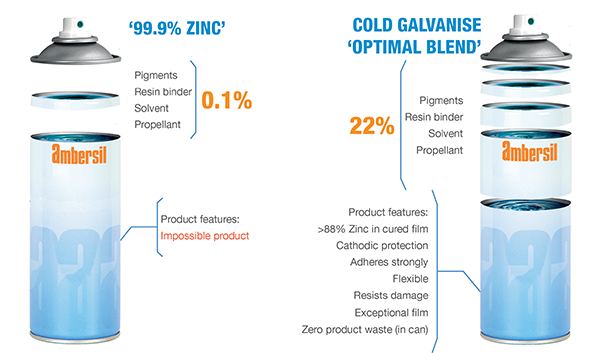

Occasionally Ambersil are asked for a 99.9% zinc spray, or if ther zinc sprays contain 99.9% zinc. The question stems from the claim many zinc sprays make, that zinc in their products is 99.9% pure, rather than the actual content itself. The International Standard fro purity is ISO 3549, and it specifies that the minimum purity level of the zinc poweder to provide effective cathodic protection should be >98%.

For an effective anti-corrosion product to function as required, a compromise must be made between the various components of the formulation to ensure that specific application criteria are met. For cathodic protection products, ISO 1461 specifies a minimum zinc content in the cured film. However, there must also be adequate resin binder to ensure that the vital zinc powder adheres strongly to the surface, with good flexibility, and resistence to cracking.

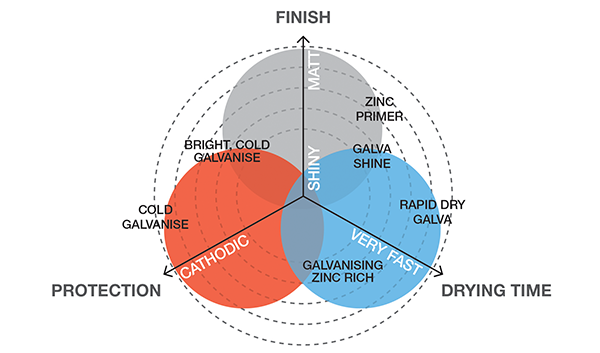

Each product in the Ambersil anti-corrosion range - including 2-in-1 paints, and acrylic topcoats - has been formulated to meet a apecific application, from full actodic protection, rapid drying, to aesthetic matching.

Each product offers different performance characteristics, and so it is important for engineers and specifiers to select the right products - or combination of products - for the best results.

Get the latest updates from ERIKS including:

Choose any or all of these via the ERIKS Subscription Centre!

Our Know+How brings together the best of the latest Know+How Hub articles in one easy to digest magazine, covering the following topics:

That's why its the leading magazine for maintenance engineers from ERIKS.

Want Know+How Magazine delivered direct to your door? Visit the ERIKS Subscription Centre to opt-in!

Take a look at our latest updates...

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

Looking for a custom Product quote? Need an answer to a Technical question? Looking for Careers/HR support? Want to work with us? Interested in our Digital Trading solutions? Have a finance question? Send us your enquiry and a member of the ERIKS team will be with you quickly.

We strive to deliver exceptional quality service and products. As part of this goal, we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

At ERIKS we strive to deliver the best quality service and products. As part of this goal we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

Call us: +441215086000