Full steam ahead - Scottish distillery with Grundfos

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

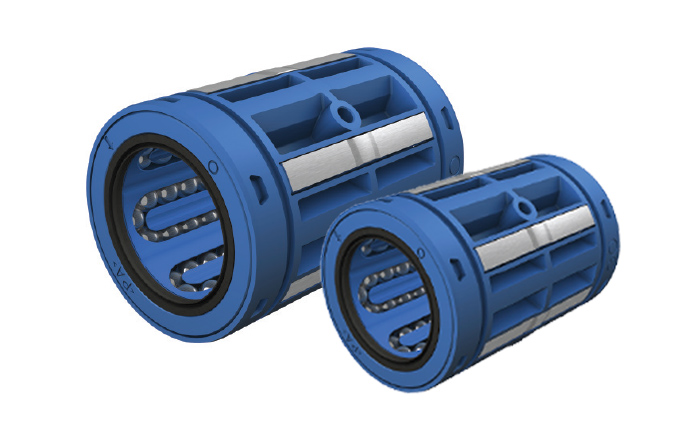

With the development and launch of its new LBC, D-series, SKF has improved still further the reliability, lifetime and performance of liner ball bearings and units.

As a result, the new generation is a must-have alternative to previous models. But why? Here are five key reasons:

Depending on the specific bearing size, the LBC, D-series linear ball bearings can deliver up to 15% higher dynamic load carrying capacity and up to 50% longer bearing lifetime compared with previous LBC designs.

This performance increase, as well as greater reliability and productivity, is thanks to aredesigning of the bearing cage and optimising of ball tracks and larger rolling elements. The higher load carrying capacity gives product designers and manufacturers the flexibility to downsize designs or to increase loading, if they have a need to.

This new generation of linear ball bearings are manufactured according to ISO 10285 dimensions and tolerances. This makes them fully interchangeable with previous LBC or ISO Series 3 bearings, and are therefore a flexible, drop-in replacement option for existing equipment designs.

Every bearing in the LBC, D-series is pre-lubricated with the optimum amount of SKF LGEP2 grease. This makes them ‘shaft ready’, which reduces assembly time and mounting mistakes. Food compatible grease and other greases are also available.

To help make bearing mounting procedures more ergonomic and simple, LBC, D-series bearings feature two indicator marks on the front side: one for main load direction, one for lubrication port position. This enables fast bearing orientation in the housing, which speeds up the mounting process and reduces the risk of errors.

The LBC, D-series includes the self-aligning LBCD .. D variant. This self-aligning variant can accommodate the tilting of the whole bearing through an angle of +/- 30 minutes of arc, compensating for misalignment caused by fitting or manufacturing tolerances, or by bending of an unsupported shaft. The LBC .. D bearing cage, seals and shields have been optimised to accommodate the self-aligning feature so that the bearing, shields and seals remain concentric with the shaft. LBCD .. D bearings ensure good running characteristics despite misalignment, which ultimately results in reduced maintenance demands and increased bearing lifetime.

The new series is currently available in the closed variant for shaft diameters of 12 to 40mm and comes with a choice of double-lip seals. Stainless steel versions are available for harsh applications; these can be combined with stainless steel guiding shafts if needed.

Like its predecessor, the new design allows linear speeds up to 5 m/s and accelerations up to 100 m/s2, and reliable operation is maintained at temperatures ranging from -20 to +80 degrees Celsius – making the bearing suitable for applications in challenging conditions.

The new bearings are a significant improvement on the older linear ball bearings currently on the market, including SKF’s own class leading offering. They are suitable for use in a wide variety of applications – including automation machinery, pick and place machines, filling machines and screen doors for trains – and are the go-to solution if you require greater performance and increased reliability from linear ball bearings.

For more information on the new SKF LBC, D-series, please contact your local ERIKS service centre or visit the SKF website.

Get the latest updates from ERIKS including:

Choose any or all of these via the ERIKS Subscription Centre!

Our Know+How brings together the best of the latest Know+How Hub articles in one easy to digest magazine, covering the following topics:

That's why its the leading magazine for maintenance engineers from ERIKS.

Want Know+How Magazine delivered direct to your door? Visit the ERIKS Subscription Centre to opt-in!

Take a look at our latest updates...

There’s steam and there’s high-quality steam. There are pump solutions and intelligent pump solution...

Looking for a custom Product quote? Need an answer to a Technical question? Looking for Careers/HR support? Want to work with us? Interested in our Digital Trading solutions? Have a finance question? Send us your enquiry and a member of the ERIKS team will be with you quickly.

We strive to deliver exceptional quality service and products. As part of this goal, we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

At ERIKS we strive to deliver the best quality service and products. As part of this goal we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

Call us: +441215086000